Working Principle of Negative Pressure Liquid Filling Machine

Working Principle of Negative Pressure Liquid Filling Machine

Working Principle of Negative Pressure Liquid Filling Machine Comparison between Negative Pressure Filling Technology and Traditional Filling Technology

Accuracy and Consistency:

1. Negative Pressure Technology: Negative pressure technology enables highly precise and consistent liquid filling through vacuumization and level control. This means the amount of liquid in each container is very accurate, reducing waste and inconsistency.

2. Traditional Technology: Conventional technology may be more susceptible to human error and, therefore, may not be as accurate and consistent as negative pressure technology.

Prevent Bubbles and Leaks:

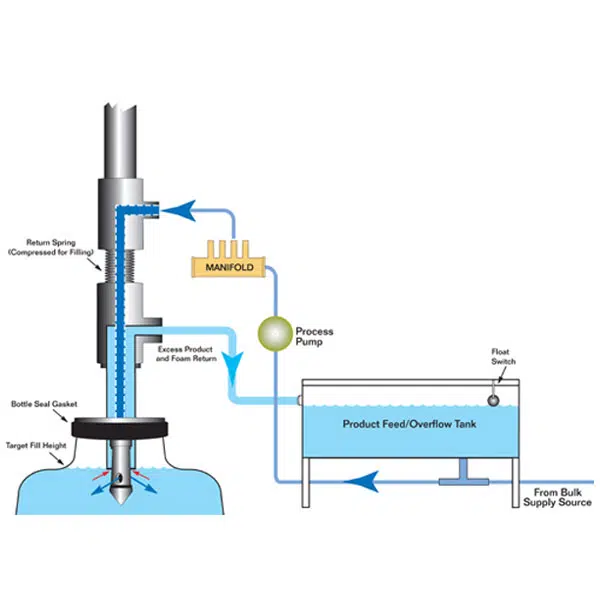

1. Negative Pressure Technology: By creating a vacuum environment during liquid filling, the formation of bubbles can be effectively prevented. For liquids that are prone to bubbles, the machine will eventually suck out all the foam in the mouth of the bottle. Inhaled foam and liquid will go into the reservoir without waste.

2. Traditional Technology: Traditional technology may require more operator skill and experience to ensure no air bubbles in the liquid and is prone to leakage issues.

Degree of Automation:

1. Negative Pressure Technology: Negative pressure liquid filling machines generally have a higher degree of automation, reducing the need for manual intervention and improving production efficiency.

2. Traditional Technology: Traditional technology may require more manual operations, including manual control of liquid flow and adjustment of fill volume.

Adapt to Different Containers:

1. Negative Pressure Technology: Negative pressure technology can adapt to different types and sizes of containers because it draws liquids through a vacuum without requiring a specific device to accommodate each container.

2. Traditional Technology: Traditional technology may require more adjustments and replacement parts to accommodate different container types.

Production Speed:

1. Negative Pressure Technology: Negative pressure liquid filling machines can always work at higher speeds because they are highly automated equipment that can work continuously.

2. Traditional Technologies: Traditional technologies may be limited in speed as they may require more operator intervention.

Application Scope

Technical Parameters:

1. Filling Nozzles: 4-16 nozzles (configured as required)

2. Capacity: 10ML-5000ML (configured as required)

3. Filling Form: Equal Liquid Level Negative Pressure Multi-head filling