Automatic Packaging is the Trend for the Development of the Food Industry

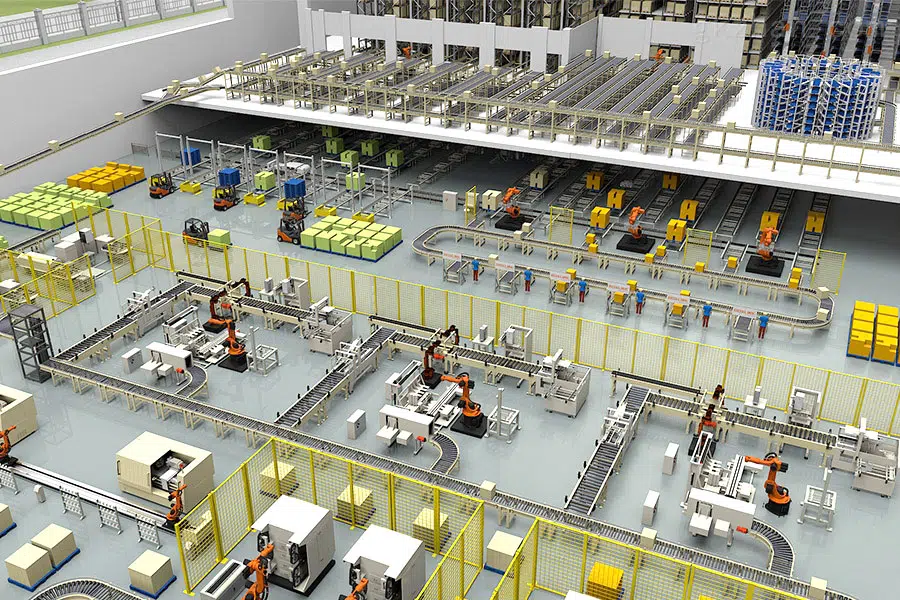

Food packaging machinery is playing an increasing role in the market, and the competition of packaging machinery is increasingly fierce. That’s obvious which low consumption, high efficiency, and multi-functional, intelligent, automatic packaging equipment is more and more favored by the industry. For leisure food manufacturers, automatic food packaging machinery use a large number of computer design and mechatronics control. It constantly helps manufacturers to improve production efficiency, and ensure food safety.

In addition, the benefits of automation technology for the recovery of redundant materials and sewage treatment are far more than the benefits of packaged food itself. So that automatic packaging is the trend for the development of the food industry.

1. The Background of Packaging Machinery Demand Surge

In recent years, on occasions like Double 11 and other e-commerce festival promotion, leisure food sales are amazing. According to the statistics, growth is driven the change of people’s dietary consumption concept and the emergence of personalized demand. With the people’s demand for leisure food increasing, the food packaging problems become the focus of social attention. Therefore, it is an inevitable trend to meet the requirements of efficiency and improve the automation of leisure food packaging.

The market of leisure food and beverage continues to grow rapidly, which drives the rapid development of packaging industry. Food packaging technology as an important part in the food industry chains has undergone the in-depth development of advanced technology. The advanced technology includes intelligence, big data, IOT (Internet of Things). Due to packaging equipment automation and personalized customization, more and more food processing enterprises adopt new equipment. It provides more market opportunities for enterprises to reduce costs and accelerate the important period of transformation.

2. Application Scenario of Automated Packaging

2.1 Packaging Trend of Snack Food

In terms of category, leisure food is diversified, including roasted nuts, sugar products, baked food, puffed food, cereal snacks, beans and bean products snacks, potato snacks dried fruit products.

When it comes to puffed food, popcorn, sunflower seeds, cereal, jelly, sugar, salt and other granular strip, vertical form fill seal packaging machine could be a better choice. The operation is very simple and convenient, and machine with advanced Chinese and English touch screen control. At the same time, with horizontal and vertical sealing temperature independent control, it adapts to a variety of food packaging materials better. In addition, the machine can achieve automatic deviation correction, automatic alarm protection function, and minimize the loss. The trend towards packaging automation is driving growth in snack food sales.

2.2 Packaging Trend of Beverage Food

The categories of beverages include packaged drinking water, vegetable protein drinks, dairy drinks, energy drinks, carbonated drinks, tea drinks and so on.

As an example, with the rapid growth of consumer demand, yogurt market continues to expand. And it becomes one of the fast growing categories of leisure food and beverage. From the perspective of packaging, yogurt packaging is diversified, including plastic bottle packaging, glass bottle packaging. The most common package is a group of eight and a group of sixteen (union cup) packaging. The union cup requires packaging machinery enterprises to carry out personalized customization according to the needs of packaging process. For example, some enterprises produce plastic cup filling equipment to meet the packaging needs of yogurt processing enterprises. Their products have advantages in the market and are sold at home and abroad. Improving packaging efficiency has become an inevitable trend of beverage packaging.

Food and beverage packaging labels are marked with net content, which needs high requirements for package weighing precision. Automatic weighing machine as a measuring instrument, except weighing, also can feed quantitative value. Meanwhile, the speed of the feed can also be adjusted. In addition, automatic weighing machine adopts advanced digital frequency conversion technology, sampling processing technology, anti-interference technology. It can realize automatic error compensation and correction, to ensure the accuracy of weighing.

3. Market Capacity

The trend of packaging automation has boosted exports of Chinese-made machinery products.

It is estimated that the global market size of intelligent packaging industry is expected to exceed 300 billion US dollars by 2023. Leisure snack and beverage and other terminal areas of intelligent packaging will also become the general trend.

It is not difficult to find that China’s packaging machinery not only meets the needs of domestic processing enterprises, but also sold to foreign markets. According to Chinese customs statistics, total exports of packaging machinery exceeded 2.2 billion US dollars. It is accounting for more than 57 percent of total exports of food and packaging machinery.

Some packaging machinery are popular and take a larger proportion in amount of export, such as beverage and liquid food filling equipment, parts of cleaning or drying machines, labeling and packaging machines. It is obvious that the exported packaging machinery products had certain competitiveness in the international market. At the same time, the technology of packaging machinery level in the international forefront, especially domestic vertical packaging machine, bag packaging machine, vacuum packaging machine, automatic weighing machine and packaging production line. The trend of packaging automation has boosted exports of Chinese-made machinery products.

4. Advantages of Automatic Packaging Machinery

Compared with the traditional food packaging machine, automatic packaging machinery in many aspects reflects greater advantages.

First of all, traditional food packaging machinery in production needs a lot of manual operations. It is inevitable that there will be absence of supervision and improper operation, easy to cause food pollution or safety risks. While, the automatic packaging machine apply sensing technology, also can detect the impurities on the production line. As well as, it eliminates unqualified products quickly, reduces the difficulty of food packaging supervision and improves the safety of food production. So that automatic packaging is the trend for the development of the food industry.

Secondly, the traditional way of transporting food from the production line to the packaging line is mostly manual handling. It wastes a lot of human labor and inefficient. Automatic food packaging machinery connect food production close, following the realization of food batch packaging processing. It makes it possible for the devices, functions and information involved in packaging to relate to each other and exchange feedback. It is not only saves time, but also improves the efficiency of packaging.

Last but not least, automation technology makes the integration of packaging machinery possible. The use of intelligent control of excess material recycling, and the production process of sewage treatment tends to be intelligent. It can improves the conversion efficiency of social resources, reduces the impact of production waste. In addition, automatic packaging machine are set up a diagnostic system in the main components, reflected in the automatic detection and maintenance of faults. As a result it can be timely and accurate troubleshooting, to ensure the normal operation of the machine.

5. Five Suggestions of Automatic Packaging Machinery for E-commerce Logistics Packaging

Automatic packaging is not only good for automatic packaging, but also good for food transportation and is an inevitable trend to improve the efficiency of logistics links.

The influence and role of packaging in the value chain cannot be underestimated. Enterprises need to reflect on the supply chain and logistics operation, and develop point-to-point packaging solutions from factory to warehouse. Automatic packaging is an inevitable trend to improve the efficiency of logistics links. The suggestions as follow:

- 1. Optimize packaging, avoid waste and improve supply chain profitability by establishing master data of product dimensions and physical characteristics.

- 2. Use IOT (Internet of Things) technology to realize intelligent packaging, ensure product safety, improve user experience, and increase the times of customer purchases.

- 3. Accelerate the automation of packaging logistics, increase the throughput of packages, improve the efficiency of packaging, loading and unloading.

- 4. Accelerate the popularization of green packaging and promote sustainable development of packaging.

- 5. Strengthen the deep cooperation between material suppliers, consumers, logistics service providers and waste management enterprises. Also break the traditional concept of packaging and take the perspective of product life cycle in treating package.

6. The Development Direction of Chinese Manufacturing Machine

Except the large-scale market demand, quality improvement, technological innovation is the source of the vigorous development of China’s packaging machinery. The market scale of domestic leisure food and beverage is rapidly expanding, and the level of industrialization, standardization and mechanization is greatly improved. It is quite clear that closely related to the rapid development of China’s packaging machinery and equipment industry.

In the future, intelligent, energy-saving, recyclable, reduce energy consumption of food packaging machinery ill become a trend and will be more popular in the market. Only in this way, we can keep pace with the times, especially under the trend of energy conservation, environmental protection, and the environment of intelligent and digital transformation and upgrading. Therefore, packaging machinery manufacturing enterprises accelerate intelligent transformation. It focuses on intelligent design, intelligent control, intelligent equipment and other aspects of breakthrough in the research and application of manufacturing technology. At the same time, developing a large distributed servo technology system can reduce energy consumption, improve intelligent packaging.

7. About VTOPS

Intelligent Packaging Machinery Leader – Zhengzhou VTOPS Machinery Co Ltd

Zhengzhou Vtops Machinery Co., Ltd. factory was established in 2001. It is located in Zhengzhou of China, in another word, it is the geographical center of China. It also is enjoying convenient transportation and beautiful environment. Its major business is including intelligent packaging machinery and installation services, and owns a 40,000 square meters of modern industrial factory. It has dozens of technical patents and invention patents, meanwhile honored with the official certification of the national high-tech enterprises.

In addition, VTOPS successfully passed TÜV Rheinland certification, therefore VTOPS became a member of Alibaba Gold Plus Supplier. Chick Here to read more of Zhengzhou Vtops Machinery Co Ltd Became The Gold Plus Supplier After Obtaining TÜV Rheinland Group Authoritative Certification.

VTOPS has an excellent foreign trade sales team and a professional after-sales service team.

Besides, VTOPS has an excellent team who focus on product development & design, quality control & inspection and company running. Dedicated to strict quality control and thoughtful customer service, the experienced staff members are always available to discuss customer requirements.

The Main Products of VTOPS

VTOPS designs and manufactures various packaging machines. More specifically, there are auger filling machine, powder filling machine, granular packing machine, pick fill seal packing machine, liquid filling machine, vertical form fill seal packing machine, labeling machine and other packaging machines. It is suitable for automatic production of food and beverage, especially on roasted nuts, sugar products, baked food, puffed food, cereal snacks, and dairy products and so on. Considering the food packaging trend, we will invest more manpower and material resources to speed up the research and development of new products and the application of patents. And continue constantly update technology to provide customers with more suitable packaging solutions.

8. More Expectations and Prospects

We encourage you to bring your filling or packing needs to us, it means giving us the opportunity to provide you with exactly what you need. We know that your products and business are valuable, when you choose one of our systems you are making a choice of guaranteed excellence. Warmly welcome customers from all over the world to cooperate with us for common success.

More information about our plant, please visit: https://www.vtops.com/3d/