Coffee Filling Packing Equipment Facing Opportunities and Challenges

Coffee filling and packaging equipment plays a central role in maintaining product quality and delivering a superior consumer experience. As consumers have higher and higher requirements for coffee quality and packaging. So coffee filling and packaging equipment improves the freshness, taste, and quality of coffee. First of all, packaging is a container for storing and transporting coffee. And it is also an important medium for brands to interact with consumers. Second, innovative packaging design and functionality can enhance consumers’ unboxing experience. Proper equipment selection is critical for any coffee brand hoping to succeed in a competitive market.

Opportunities for Coffee Filling and Packaging Equipment

Expansion of the Chinese Coffee Market

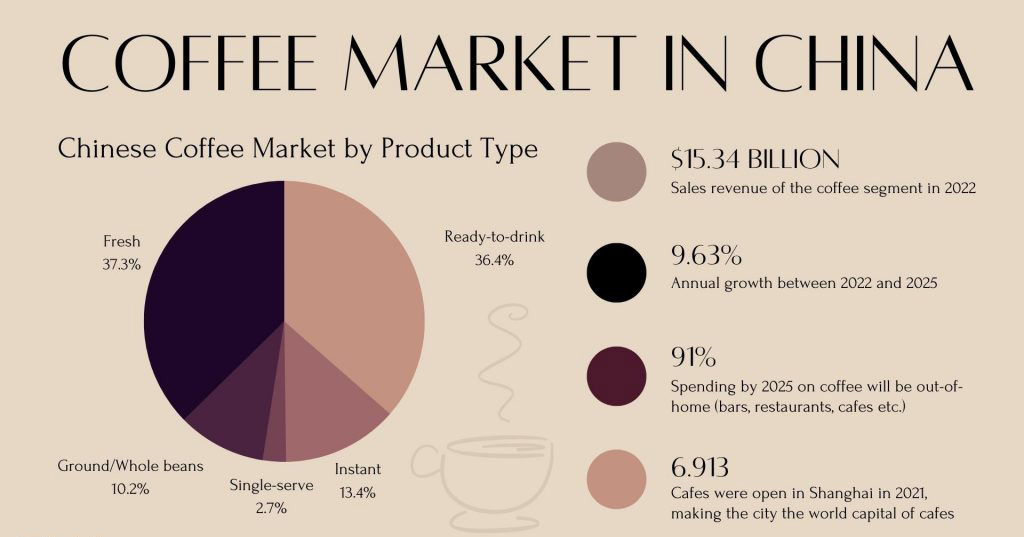

Due to the influence of coffee culture, coffee consumption in China has increased significantly in recent years. The development of the domestic coffee industry will accelerate the growth of the coffee packing equipment market.

According to public data, the size of China’s coffee market will reach 2 billion US dollars in 2023, and the per capita consumption of coffee market will reach 0.05 kg. with the improvement of people’s living standards and the continuous enhancement of coffee culture awareness, the market will grow by 7.58% per year. At the same time, China has also become a coffee exporter. In June of the 2021/22 coffee harvest year, China produced almost 2 million 60-kilo bags of coffee, up from 1.8 million bags the previous year.

Easy Joy Coffee (易捷咖啡)

Sinopec Easy Joy United Coffee Box released a new brand, “Easy Joy Coffee (易捷咖啡),” on September 3, 2019. The first batch land in 9 Sinopec gas stations in Suzhou. Introducing a variety of coffee products, such as 92# (black and white coffee), 95# (fashion special drink), 98# (boutique series), and other creative ideas combined with the scene of the gas station.

For a delicious cup of coffee, the origin of the coffee beans is very important. The cumulative planting area of coffee arrives at 615,200 mu, and the output is 220,000 tons in Linyi, Yunnan Province. Based on the rich coffee and natural resources, the area will build a comprehensive industrial cluster integrating coffee planting, processing, and R&D. Coffee shops need to package, transport and sell high-quality coffee beans. Professional coffee pouch packing machines are an important part. Due to the popularity of coffee culture, the development of domestic coffee industry will accelerate the growth of the equipment market.

For “Easy Joy Coffee (易捷咖啡),” to provide customers with a cup of delicious coffee, the origin of the coffee beans is particularly important. The cumulative planting area of coffee in Linyi, Yunnan, has reached 615,200 mu, and the output has reached 220,000 tons. Relying on rich coffee resources and natural resources, the district will build a comprehensive industrial cluster. Professional coffee packaging machines pack coffee beans, and then the packaged products are sold in coffee shops.

The Solution of Coffee Green Packaging

The solution to green coffee packaging lies in combining innovation, consumer awareness, and industry collaboration. Therefore, as consumers’ awareness of environmental protection increases, coffee brands that prioritize green packaging enjoy an advantage in market competition. Common green packages on the market are as follows:

- Biodegradable Bags: The materials used to make biodegradable bags can be completely decomposed in the natural environment for months to years, which greatly shortens the life of waste and reduces the impact of waste on the environment.

- Compostable Packaging: Compostable packaging can be placed in a composting system to break down into organic matter returning plant material to the soil.

- Recycled Material: The municipality plans to reprocess recycled materials, such as plastic, metal or paper, into packaging for new products.

- Reusable Containers: Some coffee sellers have begun offering discounts to customers who bring their containers exchange programs to reduce the use of single-use packaging.

The Ancillary Economy of the Coffee Industry

Although the coffee industry is centered on the coffee bean itself, it has also spawned a huge auxiliary economy. These include various products, services, experiences and consumers’ requirements for more diversified coffee packaging. Food packaging machinery manufacturers provide various types of coffee powder auger filler and coffee bean weighing machines to cope with changes in new forms of coffee packaging.Films, bags, glass bottles, and iron cans can all be containers for coffee packaging. At the same time, the manufacturer also designed a variety of styles and patterns of packaging and set different packaging weights to meet the different needs of different customers.

Dehong Prefecture in Yunnan Province also contributes significantly to global economic activity with its rich coffee growing resources.

Combining the development gap of the existing coffee industry chain, Dehong Prefecture has developed a coffee industry cluster, including refined sugar, milk, packaging, beverages, coffee utensils, daily chemicals and other related industries. The ancillary economy of the coffee industry plays a vital role in enriching the global coffee culture and experience. The ancillary economy also reflects the depth and breadth of how coffee impacts and is integrated into our daily lives and global commerce.

Challenges Faced by Coffee Filling and Packaging Machine

Technical and Cost Issues of Coffee Packaging Equipment

Coffee packaging equipment plays a vital role in maintaining the quality and freshness of your coffee. However, to ensure optimal freshness and shelf life of coffee, coffee filling machines require regular maintenance by skilled operators. The high initial investment and ongoing operating costs of coffee filling machines pose technical and financial challenges for companies seeking the best packaging solutions.

Environmental Regulations and Standards

As international guidelines can be stricter, coffee-filling machine manufacturers must make strategic adjustments to maintain compliance.

First of all, keep abreast of the latest international environmental protection regulations and compare them with local standards. Adopting the most stringent standards in international and local regulations to ensure compliance in various regions and simplify operation steps. Secondly, regularly educate employees on the importance of environmental protection, and training the company on the specific standards to which it complies. And finally, using automated systems to track emissions, waste, and other key environmental indicators, mitigating environmental impact.

Adapting to various environmental protection standards requires an integrated approach that combines continuous monitoring, education, technology and transparent communication. By proactively addressing these differences, coffee filling machine manufacturers can ensure compliance, reduce risk, and maintain a positive brand image.

Market Competition and Changes

The coffee filling and packing machine industry is a key part of coffee production and packaging. Coffee filling and packing machines are also constantly developing to cope with market competition and changing industry needs.

- Technological Advancements:With the rise of Industry 4.0, the integration of coffee filling machines with automation, artificial intelligence and IoT capabilities finally increases the efficiency and accuracy of the machines.

- Sustainability Focus: With the growing global focus on sustainability, coffee filling machine manufacturers need to redesign their coffee filling machines. While using environmentally friendly packaging materials and minimizing waste and energy consumption.

- Diverse Packaging Options:The coffee packaging machine has a variety of packaging forms to meet different needs in the market. Certainly from traditional sachets to single-serve capsules to suit different consumer preferences.

- Global Competition:The influx of manufacturers from regions with lower production costs has challenged established brands.

- Quality and Safety Standards: According to strict food safety regulations, coffee filling machines are manufactured to meet higher hygiene and quality standards.

- After-Sales Support and Training: To differentiate themselves in the competitive market, manufacturers offer a wide range of after-sales support, maintenance services, and operator training programs.

Conclusion

Growth in the global coffee industry and changing consumer preferences paint a promising picture for future of coffee filling machines. Meanwhile, as awareness of environmental responsibility grows, the demand for sustainable, biodegradable or recyclable packaging materials will surge. Due to the further enhancement of artificial intelligence and automation capabilities in the future, coffee filling machines can achieve a more accurate, faster and consistent packaging process. Since space is at a premium, especially in urban production facilities, scalability and compactness must be considered in equipment design. With the continuous development of the coffee industry, the prospects for coffee filling and packaging equipment will be bright.