A Complete Customized Milk Powder Packing Line Ship to United States

Zhengzhou Vtops Machinery Co Ltd successfully delivered a complete customized milk powder packing line to United States of American on August 31, 2020.

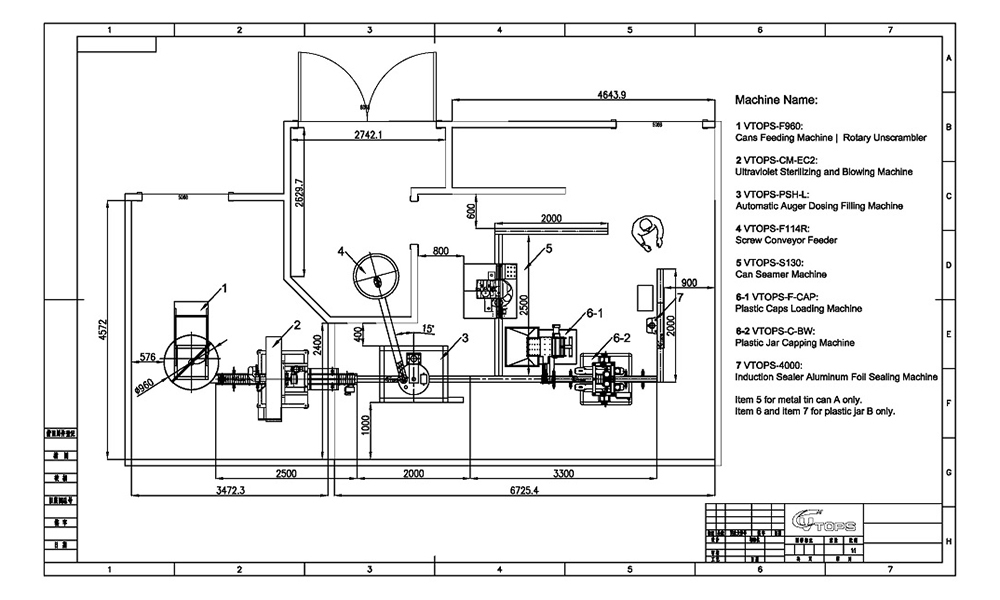

The customized milk powder packing line included 7 machines are the following:

- 1, A cans-feeding machine of model VTOPS-F960 with 960mm turntable;

- 2, A non-magnetic empty container sterilizing machine of model VTOPS-SM-EC2;

- 3, An auger filling machine of model VTOPS-PSH-L;

- 4, A seaming machine of model VTOPS-S130 for metal cans with the diameter of 155mm;

- 5, A four-wheel clamping twisting capping machine of model VTOPS-C-4W for plastic jar with diameter of 127mm;

- 6, An aluminum foil induction sealing machine of model VTOPS-4000 for the cap of plastic jar.

Get the Inquiry

Mr. JH is a founder of a nutritional powder factory in the United States of American. He sent an inquiry of milk powder packaging solution to VTOPS on May 8, 2020. He needs a complete one line of bottle-feeding cleaning filling capping seaming machines.

Due to the local government where Mr. JH works has extremely high requirements for food production, Mr. JH needs a professional packaging company to help him complete the milk powder production line project. After browsing the website of vtops, he learned that vtops is a packaging machine manufacturer since 2001 of production experience and rich experience in milk powder filling lines. Therefore, Mr. JH sent an inquiry and got Ms. Lisa’s connection soon.

Details and Solutions

During the discussion, Ms. Lisa learned about Mr. JH’s needs in detail, and she discussed with the engineer to provide a variety of solutions, which enabled the project to progress smoothly and was approved by JH’s local food safety department.

Here are Problems and Solutions mentioned by both parties on the project as below:

Question 1: Three kinds of Container

| Container | Type | Body Size | Lid | Filling Weight |

|---|---|---|---|---|

| A | Metal Tin Can | φ162mm | — | 1700 grams |

| B | Plastic Jar | φ127mm, H152mm | φ110mm | 1200g |

| C | Pail | φ254mm, H254mm | — | 5kg |

A. Tin Can

The diameter of the can exceeds the standard size of 160mm

Solution: VTOPS customized the mold based on the size to meet customer sealing requirements.

C. Bucket:

The size of the barrel far exceeds the standard size of 152mm

Solution: VTOPS widened the width of the disinfection channel to meet the large bucket size.

Question 2: Local Hygiene Testing Requirements

A. Sterilization: different sterilizers are suitable for different container materials, according to the customer’s container size and material.

Solution:

a. Ultraviolet Sterilizing and Blowing for Tin Can and Plastic Bottle.

b. Empty Cans Sterilizing Machine for bucket.

B. Dust Proof:Sterilizing, Filling, capping, seaming machines are required by cover.

Solutions: Equip with Plexiglass Room and Plexiglass Cover accordingly.

Question 3: Limited Space and Layout:

The diameter of the can is large. If the conveyor belt is too short, it will affect the transportation of the can. In other words, the containers cannot be transferred with short distance.

In addition, because of the space problem, no cap feeder is added to manually place the cover, so more space is required.

How to lie out in a limited space, not only must ensure the distance of the conveyor belt between each machine, but also leave a certain amount of space for personnel to operate. These are the key points that need to be discussed and resolved at that moment.

After discussions and adjustments between the two parties, a satisfactory layout was finally made.

Contract and Production

Soon, Ms. Lisa updated the final quotation and delivery time based on all the machines Mr. JH need. Mr. Joho fully understands that VTOPS needs enough time to customize all of his machines, and the higher cost of customization. But VTOPS offered a very fairly reasonable price, he was much appreciated with the price and the service VTOPS provide.

On June 20, VTOPS received the payment and all samples from Mr. JH. VTOPS soon start the production and finished the complete customized milk powder packing line on August 26.

Over the years, VTOPS have always put customer needs first, and with their own professional services and product quality, they have won praise from customers at home and abroad. VTOPS will not stop here; we will do better in the future.