A Pet Food Weighing Filling Canning Line Customized for Russian Client

Image Description:

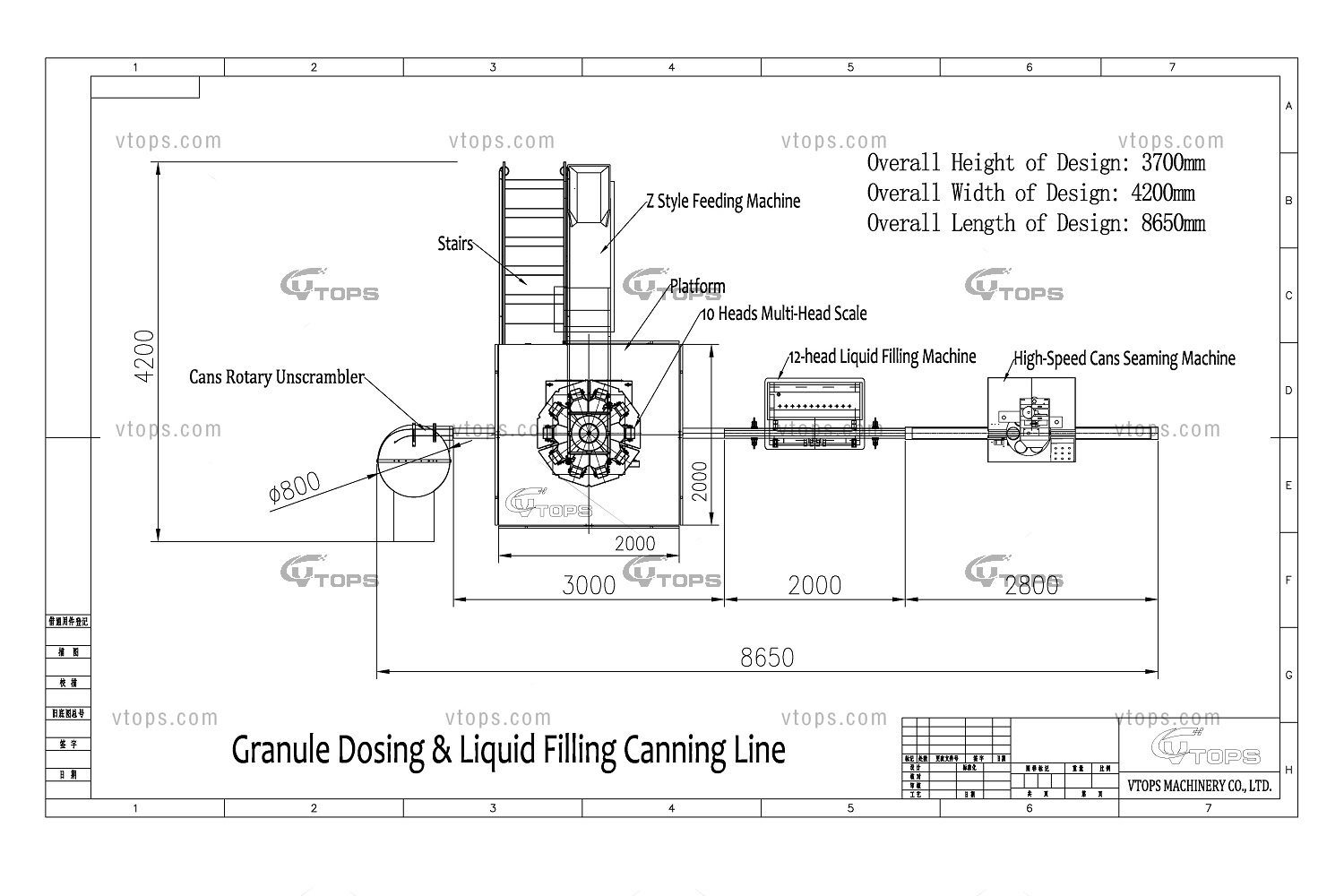

As shown of CAD drawing, the overall dimensions: Length: 8650mm; Width: 4200mm; Height: 3700mm.

Image Description:

As shown of CAD drawing, the overall dimensions: Length: 8650mm; Width: 4200mm; Height: 3700mm. An Introduction

The weighing filling production line works in the following way:

Metal cans are loaded onto the conveyor belt, granule of specified weight are put into the cans by 10-head weigher, and liquid of specified weight are filled into the cans by a liquid filler with 12 nozzles, and then sealed.

The pet food filling production line include:

- Cans Rotary Unscrambler;

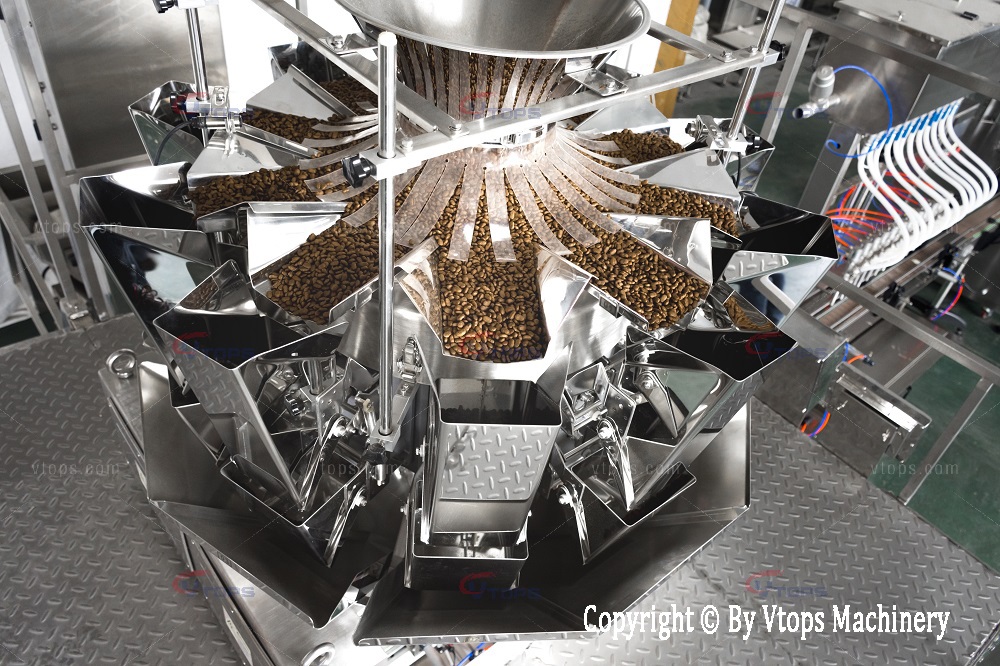

- Multi-Head Weigher;

- Platform;

- Control System for Multi-Head Weigher;

- Z style feeding machine;

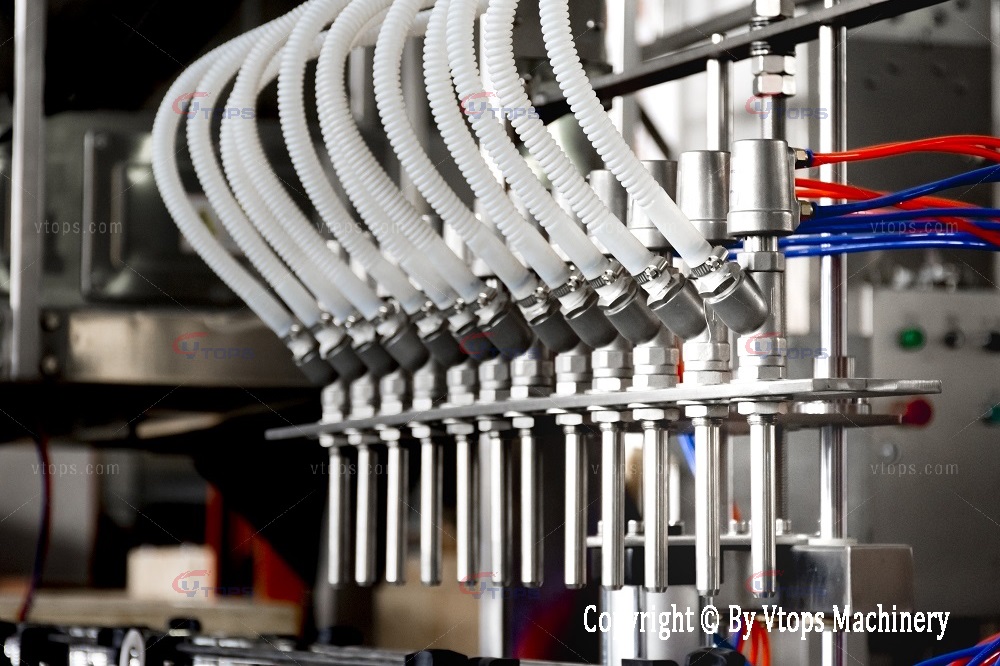

- Liquid Filling Machine with 12 Nozzles;

- High-Speed Cans Seaming Machine;

Acceptance Testing

Part One:

- 42 with a filling weight of 203 grams (the container weighing 37 grams and the ‘zero error rate’ was 82.35%;

- 8 with a filling weight of 204 grams (the container weighing 37 grams);

- 1 weighted 202 grams (the container weighing 37 grams) and the error was only 1 gram.

Part Two:

- 2 cans weighed 285 grams (the container with a weight of 37 grams);

- 5 cans weighed 286 grams (the container with a weight of 37 grams);

- 3 cans weighed 287 grams (the container with a weight of 37 grams);

- 2 cans weighed 288 grams (the container with a weight of 38 grams).

Part Three:

How did they get in touch?

Ms Galina Le found VTOPS through google, and took interest in the machines and filling line solutions after watching videos of VTOPS products on Youtube.

Mr Chang said that the factory had not received Russian clients before, but there were clients from Russia who purchased Vtops machine online. The latest client sent an email to ask about the quality of the machine to one of the previous clients who commended VTOPS product quality and after-sale services.

During their inspection, the engineer nodded his head for several times when he read the final results. The translator said Mr Rogalev Iurii was quite satisfied. Mr Chang added that the client was strict with precision and only a error of 5 grams was allowed.

Zhengzhou Vtops Machinery Co., Ltd is a specialized Design Manufacture since 2001. It designs, develops and manufactures various types of auger fillers and provides customized solutions and superior services.

“Our company is committed to provide all kinds of filling and packing solutions. We have cooperated with clients from pet food industry before and always strive to provide the most suitable solution to meet their requirement”, Mr Chang said.

Perfect After Sales Service

Related Links:

[1] CAD Drawing of Canning Line for Granule Weighing and Liquid Filling;

[2] Mr Rogalev Iurii visit Vtops Machinery for Pet Food Weighing Filling Canning Line;