Powder filling packaging technology has been rapidly evolving in recent years, driven by advancements in automation, precision, sustainability, and flexibility. These trends are transforming the ways of powdery products filling and packaging, making the process more efficient, accurate, and eco-friendly.

1. Automation:

The future of powder filling packaging technology is likely to be dominated by automation. Automated powder filling machines have been gaining popularity in recent years due to their ability to handle large quantities of powder and reduce the need for human intervention.

In the future, we can expect these machines to become even more efficient and precise, with the integration of smart sensors, machine learning algorithms, and real-time monitoring. These technologies will allow manufacturers to improve their filling process and minimize errors, reducing costs and improving overall product quality.

2. Sustainability:

Sustainability is an important consideration for the future of powder filling packaging technology. For Net-zero commitments by 2050, consumers are becoming increasingly concerned about the environmental impact of packaging. It leading manufacturers to seek out more eco-friendly solutions.

In the future, we can committed to see more sustainable packaging options, such as biodegradable or compostable materials, recycled materials, and reusable containers. Machines that can handle these materials will be in high demand. And those that can integrate with other sustainable packaging technologies, such as bulk dispensing systems, will become more popular.

3. Flexibility:

As market demand shifts and customers’ needs change, manufacturers need to be more responsive to the changing environment. Machines that can handle a wide range of powders and adjust filling quantities will be essential to meeting this demand.

In the future, we committed to powder filling machines to become even more flexible. Not only with the ability to deeply integrate with other packaging technologies, such as capping and labeling, but also to create customized packaging solutions for every individual customers.

4. Industry 4.0:

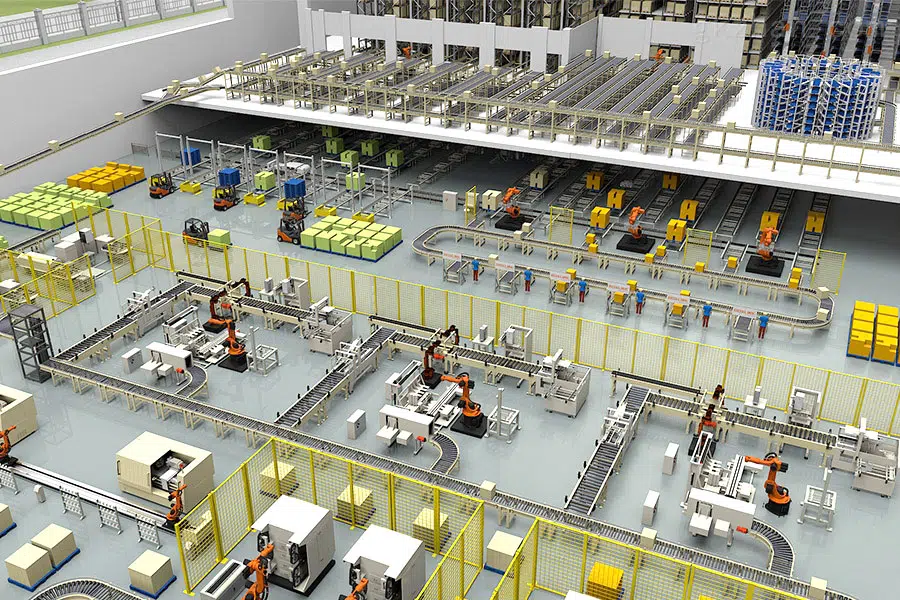

Industry 4.0 is the term used to describe the current trend of automation and data exchange in manufacturing.

In the future, powder filling packaging technology is likely to become more integrated with other manufacturing technologies, such as robotics, artificial intelligence, and the Internet of Things (IoT). This integration will allow manufacturers to improve their production process, reduce costs, and optimize their supply chain.

5. Personalization:

Personalization is becoming increasingly important in the packaging industry, as consumers seek out unique and customized products.

In addition, in the future, powder filling machines may become more personalized. Personalized powder filling and packaging machines are more in line with customer needs. The ability to create unique packaging solutions for individual customers will get better development. This could include personalized containers, labeling, even packaging design.

Conclusion

The future of powder filling packaging technology is likely to be characterized by automation, sustainability, flexibility, industry 4.0, and personalization. These trends will drive the development of new technologies and packaging solutions, allowing manufacturers to create more efficient, eco-friendly, and customized products to meet the changing needs of consumers and markets.