High Quality Wire Nail Packing Machine Supplier

Wire nails are widely used as fasteners. Do you know how many kinds of wire nails? Are you curious how the wire nails are manufactured, packaged, and shipped? And are you know a reliable wire nail packing machine will reduce your cost, not only the transportation cost but also the labour cost.

1. Classification and Application of Wire Nails

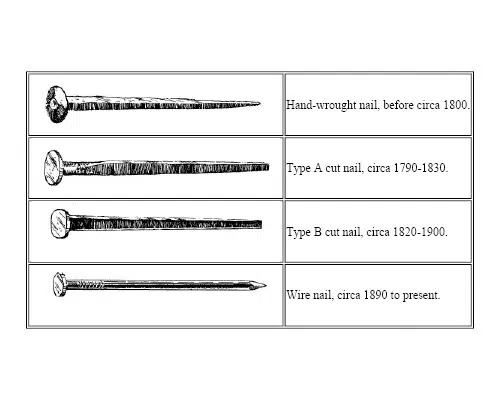

Until the mid-19th century, all nails used were forged or cut, so we called them Cut Nails. Either it is heated in forging and then shaped, or it is cut from a strip of material and upset at one end to form ahead.

Wire Nails History

These styles of nails mostly disappeared in the late 19th century because cheaper nails made of wire nails took over. Here are several common wire nails are the following:

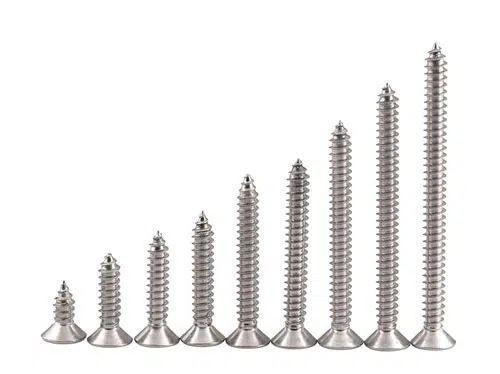

1.1 Wood Screws Wire Nails

Wood Screws Wire Nails

Description: Wood screws are similar to machine screws. The difference is that the thread is a particular thread for wood screws, which can be directly screwed into the wood components. It is suitable for fastening a metal (or non-metal) part with a through-hole to wood components. This connection is also removable.

Application: It combines metal or other materials and wooden materials. It is also mainly suitable to fix the metal plate net, screen and indoor external hanging line. At the same time, it can also be suitable to fix the steel wire binding wooden cases.

Function: When applied to engineering, carpentry and architecture, a nail is a pointed piece of hard metal (usual steel) suitable to fasten wood. Hammers drive nails into objects; sometimes, electric nail guns or gas nail guns instead also can drive nails into objects. Nails stabilize objects by their deformation and by friction. It plays the role of reinforcement.

1.2 Twist Screw Nails

Twist Screw Nails

Twist Screw Nails body looks like a twist shape, and the head is round flat. The bottom is pointed, and the nailing force is powerful. It is suitable for some places that need strong nail force, such as drawers wooden ceilings. Twist screw nail is mainly suitable for material transmission and large drills.

1.3 Self-tapping Screw Nails

Self-tapping Screw Nails

Self-tapping screw nails is a quick fastener with a galvanized passivation surface. They are suitable for connecting thin metal plates (steel plates, saw plates, etc.). When connecting, the threaded bottom hole of the connecting piece is in advance, and then the tapping screw is screwed into the threaded bottom hole of the connecting piece. It mainly connects and fixes metal components, such as aluminium alloy doors and Windows.

1.4 Cement steel nails

Cement steel nails

Cement nail, also known as steel nail, is made of 45# mild steel or 60# mild steel. Its characteristics include hardness, thickness, short, intense penetration, and smooth surface. It is the ideal building nail with high nail force that can be directly nailed into an ordinary brick wall, 260# 280# cement mortar block, silicate and other structures.

1.5 Nails for other uses

Other uses of wire nails, such as staple nails, are suitable in corrugated cartons ridging nails (wooden boat nails).

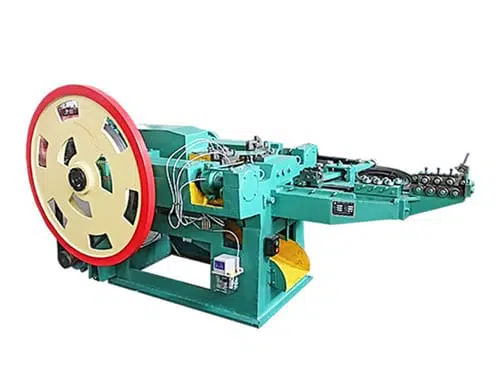

2. How Are Wire Nails Made?

The production process of nails is mainly drawing, cold heading, polishing and other technological processes. With the help of the power of the machine, the highly durable carbon steel wire is drawn out and put on the rotating drum. After continuous pulling, the steel wire has been rolled up to the size. Cut into a short piece of stick with a machine and then electromagnet them to the designated machine, the nail head and tail treatment. The sharp end of the nail is made with hydraulic pliers, and the other end is hammered flat with a press to press out the nail head. The nail is made. These processes can also be added if the nail surface is needed for electroplating or blackening.

The process flow is as follows:

2.1 Fixture Dies

The wire is pulled from the coil and fed into the wire nail making machine, held by a pair of fixture dies. The shape of the nail head has been machined to the end of the mould.

wire nail making machine

2.2 Forming the Nail Head

As the mould clamps the wire into place, the free end of the wire is struck by a mechanical hammer. This deforms the end of the line into the cavity to form the nail head.

2.3 Moulding

The wire is still clamped in the mould, and a modular cutter strikes the other end of the nail to form a tip and cut the nail, separating it from the rest of the wire coming off the coil.

2.4 Multiple loops

The mould opens, and the ejector drives the nail into the collection plate below the machine. The free end of the wire is pulled out of the coil and fed into the machine. Then the cycle starts again.

Most nails are made from coils of wire. The wire is fed into a nail machine that produces up to 700 nails per minute. The nails can then be further twisted or shaped, cleaned, finished and packed.

Therefore, the nail manufacturer can place different moulds according to the demand to produce different threads, diameters, and lengths of wire nails.

3.How are Wire Nail Packing Automatically?

3.1 Background

Every year, the world manufactures a large number of wire nails. These nails need to be packaged before transportation. This seemingly simple problem but very complicated.

Iron nails are a large number of messy pieces. There will be weak packing, easy damage, a large gap between nails, and other shortcomings. For example, when nails are packed, the box will become very bulky if nails are not arranged neatly. Therefore, it is necessary to sort the nails when packaging to arrange them as neatly as possible. It reduces the volume of the packaging and the transportation cost and prevents the nails from piercing the packing case.

Sorting packaging of wire nails will take up a lot of labor, and the efficiency of packing is very low. It cannot meet the strong demand of the current market. Wire nail packing is the last process of nail production. For efficiency, it is necessary to adopt automatic packaging equipment.

3.2 Classification of Packaging

The have some common packaging requirements of wire nails are the following:

3.2.1. Same nails in one bag

The same model products if need to packing into the same number of small packages. Since each product is produced by the same mould and has the same weight, it should be weighed by multi-head scales or divided into equal parts according to the number. It will be exact by automatic packing of weighing, such as the Multi-head Weigher Machine would be ideal choose.

Multihead Weigher (Weighing Packaging)

The working video of Wire Nail Multihead Weigher Packing Machine are the following:

3.2.2 Different nails in one bag

Suppose the products of different models need to packaging in one bag or pouch. Therefore one or some vibrating bowl will help count. In this way, accuracy and efficiency will have ensured.

Wire Nail Vibrating Bowl (Packing)

The working video of Wire Nail Vibrating Bowl Packing Machine are the following:

3.3 Processing of Packaging:

- 3.3.1 Put the raw material (nails) into a hopper.

- 3.3.2 Use a magnetic elevating device to transport nails.

- 3.3.3 Weighing nails, the machine will calculate the raw material (nails).

- 3.3.4 Use vibrating tray reactor and nail counter device will complement the deficiency raw material (nails).

- 3.3.5 Packing nails into a bag and then finished (sealing and cutting) bag completed.

3.4 Advantages of Packaging

- 3.4.1 Customized vibratory disks aiming at screws/heterotypic parts, precision counting control device ensure every bag correct.

- 3.4.2 Full automatic packaging machine adopts mechanical cam structure, enabling the whole machine to safer, more stable and reliable.

- 3.4.3 Advanced PLC control system, automatic stop during failure, automatic alarm, automatic diagnosis, safe and simple for use.

- 3.4.4 Automatic feeding, counting, heating, packaging, variable packaging speed, failure display, etc.

- 3.4.5 Unique packaging and sealing technologies make the seal beautiful and firm.