How to Choose the Best Inline Checkweigher System for Your Food & Beverage Production

Maintaining consistent product quality is crucial for any food and beverage brand. A single product recall can cost a company millions, tarnish its reputation, and erode consumer trust. While most businesses focus on eliminating physical contaminants like metal shavings, glass, and plastic, ensuring precise product weight is another vital aspect of quality control.

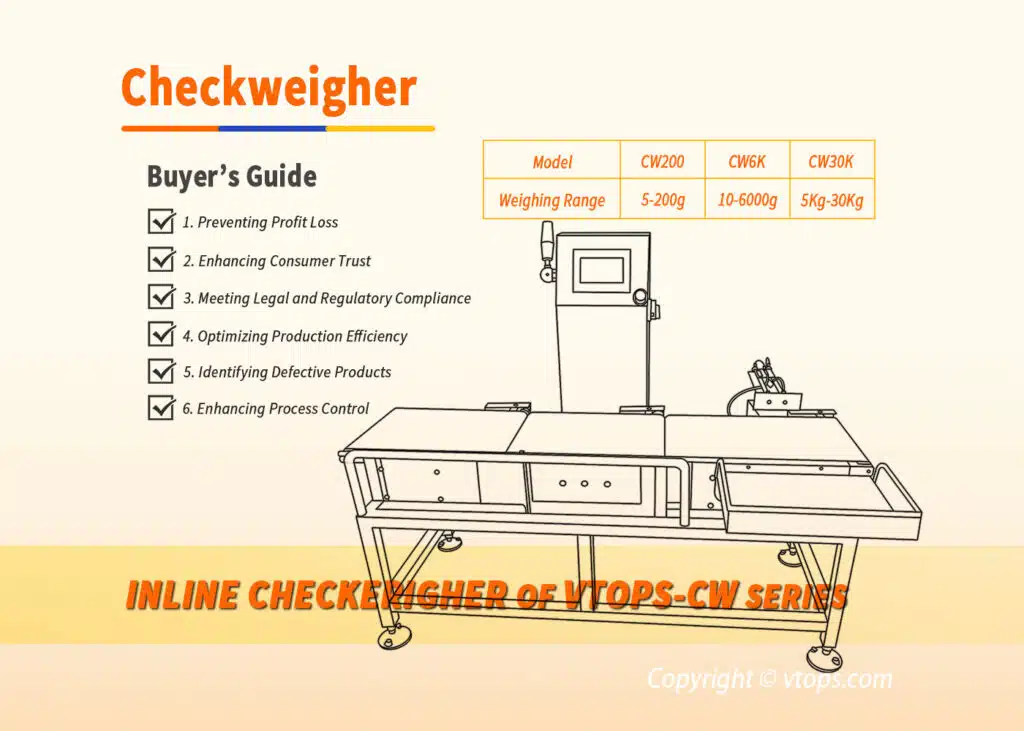

At VTOPS, we understand the importance of weight accuracy in food packaging. Our high-performance inline checkweighers provide real-time weight monitoring, ensuring that every product meets weight regulations and consumer expectations. In this article, we’ll explore how checkweighers benefit food and beverage manufacturers and why integrating them into your production line is a smart investment.

What is a Checkweigher?

A checkweigher is an advanced inline weighing system that verifies product weight as it moves through a production line. Unlike standard conveyor belt scales that merely record weight, checkweighers take corrective action—automatically rejecting underweight or overweight products to ensure quality consistency.

A typical checkweigher consists of three key components:

- Controller – Collects weight data and determines if the product meets specifications.

- Weighing Platform – Accurately measures the product weight in motion.

- Rejection System – Automatically removes non-compliant products from the production line.

Checkweighers are widely used in industries where weight accuracy is critical, including food, beverages, pharmaceuticals, cosmetics, and consumer goods.

The following video shows the application of inline weighing rejection in the milk powder canning production line (start form 55 seconds):

1.6Kg 2.5Kg Baby Formula Milk Powder Φ153mm Φ189mm Tin Can Filling Seaming Canning Packaging Line

Why Checkweighers Are Critical in the Food Industry

1. Preventing Profit Loss from Overfilling

Even small overfills can result in substantial financial losses over time. Excess product, often called “giveaway”, means manufacturers are providing more than necessary without additional revenue. A checkweigher helps eliminate this waste by ensuring precise portioning, ultimately boosting profitability.

2. Enhancing Consumer Trust

Consumers expect to receive the exact amount of product as stated on the packaging. Whether it’s a 500g bag of rice, a 1L bottle of juice, or a pack of chocolates, weight discrepancies can lead to dissatisfaction, complaints, and loss of brand loyalty. Checkweighers ensure consistency, building consumer trust in your products.

3. Meeting Legal and Regulatory Compliance

Government regulations in the food industry, such as those from FDA, USDA, and NIST, require strict adherence to weight accuracy and package labeling laws. Unlike traditional spot-checking, inline checkweighing inspects 100% of products and prevents costly fines or recalls caused by non-compliance.

4. Optimizing Production Efficiency and Reducing Waste

A checkweigher provides real-time feedback, allowing manufacturers to identify and address production inefficiencies. Underfilled packages can indicate issues such as:

- Malfunctioning filling machines

- Product leakage or packaging defects

- Inconsistent ingredient distribution

By quickly detecting and correcting these issues, businesses can minimize material waste and enhance production line efficiency.

5. Identifying Defective Products and Packaging Issues

A checkweigher does more than just verify weight—it also helps detect damaged or improperly sealed packages. Underweight readings may indicate:

- Leaking pouches or bottles

- Broken seals leading to product loss

- Missing product components

By automatically rejecting faulty products, checkweighers reduce rework, prevent recalls, and ensure only high-quality products reach consumers.

6. Automating Sampling for Higher Accuracy

Traditional manual weight sampling is time-consuming and prone to errors. Inline checkweighing automates this process, ensuring continuous and accurate inspection of every package. This eliminates the need for manual testing, reduces labor costs, and improves operational efficiency.

7. Enhancing Process Control and Predictability

Checkweighers provide valuable data insights that help manufacturers predict and improve their production process. By monitoring ingredient batch weights and pre-cooked product weights, manufacturers can ensure consistent quality and uniform processing, preventing product inconsistencies.

Maximizing Inspection Efficiency with Combined Solutions

While checkweighers ensure weight accuracy, integrating them with metal detectors and X-ray inspection systems provides a comprehensive quality control solution.

- Metal Detectors – Identify metallic contaminants in food and beverages.

- X-ray Inspection Machines – Detect non-metallic contaminants like glass, plastic, and bone fragments.

By combining these technologies, manufacturers can save space, enhance inspection accuracy, and ensure complete product safety, all within a streamlined production line.

Why Choose VTOPS Checkweighers?

At VTOPS, we specialize in high-precision packaging solutions designed for the food and beverage industry. Our systems are custom-built to integrate seamlessly into your production line, helping you:

- Minimize product giveaway and maximize profits

- Ensure compliance with global food safety regulations

- Improve packaging efficiency and reduce material waste

- Detect product defects before they reach the market

- Enhance production speed without compromising accuracy

- 40,000㎡ manufacturing facility to accommodate any customization needs

- Free 2-year warranty for worry-free operation

With over 20 years of experience in the packaging machinery industry, VTOPS is a trusted supplier in checkweighing and quality control solutions.

Final Thoughts

A checkweigher is not just a tool—it’s an investment in quality assurance, regulatory compliance, and business profitability. By implementing a reliable, high-performance checkweighing system, food and beverage manufacturers can enhance consumer trust, reduce costs, and optimize their production process.

If you’re looking for a checkweighing solution tailored to your needs, contact VTOPS today and let our experts help you achieve the highest level of product quality and efficiency.

📩 Get in touch with us to learn more about our checkweighers and inspection solutions!