8 Important Considerations When Buying an Induction Sealer

When you are buying an aluminum foil induction sealer, this article elaborates on 8 important considerations are following for your reference.

Type of Lids

The product being packed has a role in determining the best type of lids for induction seal to use. A protective layer or barrier layer may be required if the product includes any potential harm or volatile elements. If you want to keep corrosion at bay, you may sandwich it between the heat-sealing film and the foil.

The nature of the content will help you decide the kind of lids appropriate for your packaging. You can choose from the child-resistant lid, continuous–thread lid, and dispensing lid based on your business requirements.

Another most significant factor to consider when sizing the induction sealer machine is the diameter of the foil. Usually, a bigger one will take more energy to seal. Therefore, if a variety of containers are to be sealed, the system must be sized to accommodate the full range of lids.

Cooling Ways

An induction sealer typically employs two cooling methods: Air Cooling and Water Cooling. A water-cooling induction sealer machine is mainly utilized to seal individual packages and containers that contain liquids.

Our customers may choose from various Air Water Cooled Induction Sealer Machines with Bottle Conveyor that we provide. Both air-cooled and water-cooled foil sealer machines are made following international quality standards. The induction sealer machines are also modified to meet the customer’s needs. You can contact VTOPS and receive your induction sealer machine at a competitive price if you need it.

Although water-cooled foil sealers have higher cooling efficiency. But for safety and convenience reasons, we prefer air-cooled cooling.

Jamie Parker

Induction Sealer Machine Price

It is wise to know the range of each type of induction sealer machine price because it varies with the manufacturing companies. It would help if you also thoroughly understood the induction sealer machine’s qualities, including portability, power supply, and weight, determining the cost. As a result, you will be able to choose the most cost-effective option for your needs readily. It is vital to calibrate your machine to maximize the amount of work completed in a given amount of time. You must check the machine’s speed, power supply, and sealing capabilities. These aspects may help you save money when you choose the right induction sealer machine. Additionally, knowing all these will help you compare the price ranges of the induction sealer machines that fall into a comparable classification.

Degree of Automation

One of the most critical limits on induction sealing processes is the degree of automation of the induction sealer machine. With the manual or handheld induction sealer machine, there will be much time consumed but less power utilized. In addition, a handheld induction machine may pose some health risks. The price of a handheld induction foil cap sealer machine may seem low, but it rapidly becomes outrageously expensive. You only manage up to 6 containers per minute.

With a semi-automatic induction sealer machine, the work rate will be boosted. When using this machine, you can manage to seal up to 16 bottles every minute.

Lastly, using a fully automatic induction machine offers you an opportunity to seal the most number containers over the duration. You can manage to seal up to 25 bottles in a minute. Therefore, depending on your business needs, you can choose an induction sealer machine with the level of automation that will match your needs.

Technical Support

The technical specifications of an induction sealer machine must be taken into consideration at all times. It is recommended to choose a system that is capable of performing a wide range of duties. You should look for an induction sealer machine that can seal containers of varying sizes and forms, among others.

The other thing to check is the production speed of the machine, which is significant in increasing the output of the production unit.

It is also important to understand the maintenance schedule for the machine. This will help you evaluate whether you will be able to afford any expenses incurred.

Warranty

Verify the warranty period before completing the purchase of your preferred induction cap foil sealer machine. The elements included by the warranty are the most significant factors to examine carefully. Those steps will allow you to prepare ahead of time for how you will manage and service the induction sealer machine. As a result, if a problem arises due to lack of proper management, if it is not understood the warranty policy of manufacturer’, and if is not covered by the warranty provided. Then you have to pay unnecessary expenses.

Additionally, It is pleasure that VTOPS provides all foils sealer machines with a warranty of 2 years. If the foil sealer machine is damaged, VTOPS will replace it with new accessories free of charge.

Electrical Requirements

Knowing how much power it uses before buying a suitable induction sealer machine for your company. More power will have a higher output and lead to higher output. Of course, higher power will consume more power, and the machine itself is relatively more expensive. Consider whether it will be cost-effective to supply such amount of power rated.

Also, It is good to double-check if the induction sealer machine of your choice will work with a residential or commercial power supply.

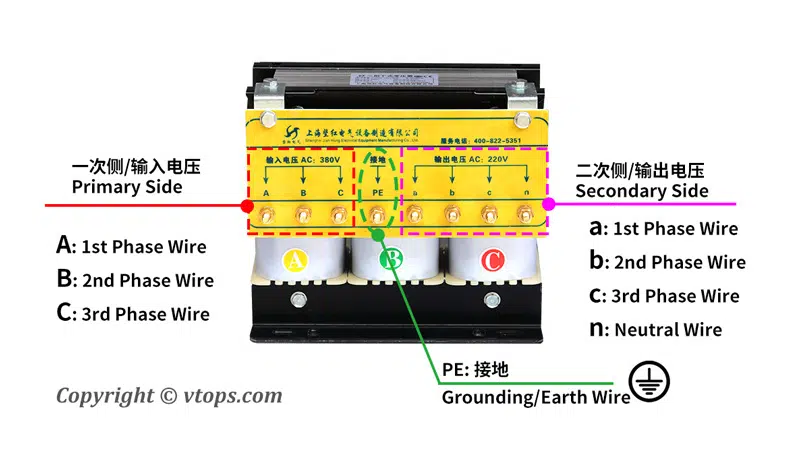

If your voltage doesn’t match the induction sealer machine, a voltage transformer will help you out. How to wire the voltage transformer, please refer to here.

Size of Factory

The buying of induction sealer machine, whether manual or automatic, is mainly dependent on the size of the factory. In other words, it depends on the usage scenario. A fully automatic induction machine is necessary to maximize the sealing process, but this would be best suited for a medium to a large company. In the case of a small-scale factory, manual and semi-automatic induction sealer machines may be cost-effective.

Also, the giant factory may require more induction sealer machines to meet the optimal output. On the other hand, a smaller factory may use limited induction sealer machines to avoid constraints on expenses. As a result, you should assess the size of your firm and the expenditures you can afford to purchase a given type and number of induction sealer machines.

Conclusion of Buy the Right Induction Sealer Machine

You already know all you need to consider when buying the right induction sealer machine. The major function of an induction sealing machine is to create caps seal for containers to eliminate the chances of content leaking. The machine ensures that the caps are tamper-proof, help to keep freshness, and promotes prolonged shelf life of the content.

Compared to other sealer equipment, the induction sealing machine is outstanding in the safe packaging of your products. Using an induction sealing machine is essential to the production of packages in the packaging business. An induction sealing machine may be used to seal a wide range of items, including pharmaceuticals, nutritional supplements, dairy products, food, and beverages, as well as chemical pastes and paints.

Above all, investing in a high-performance induction sealer machine will save you a lot of time and effort. It also ensures recouping a significant portion of your investment.