One Regular Set of Powdered Baby Milk Canning Packing Line Ready For Delivery

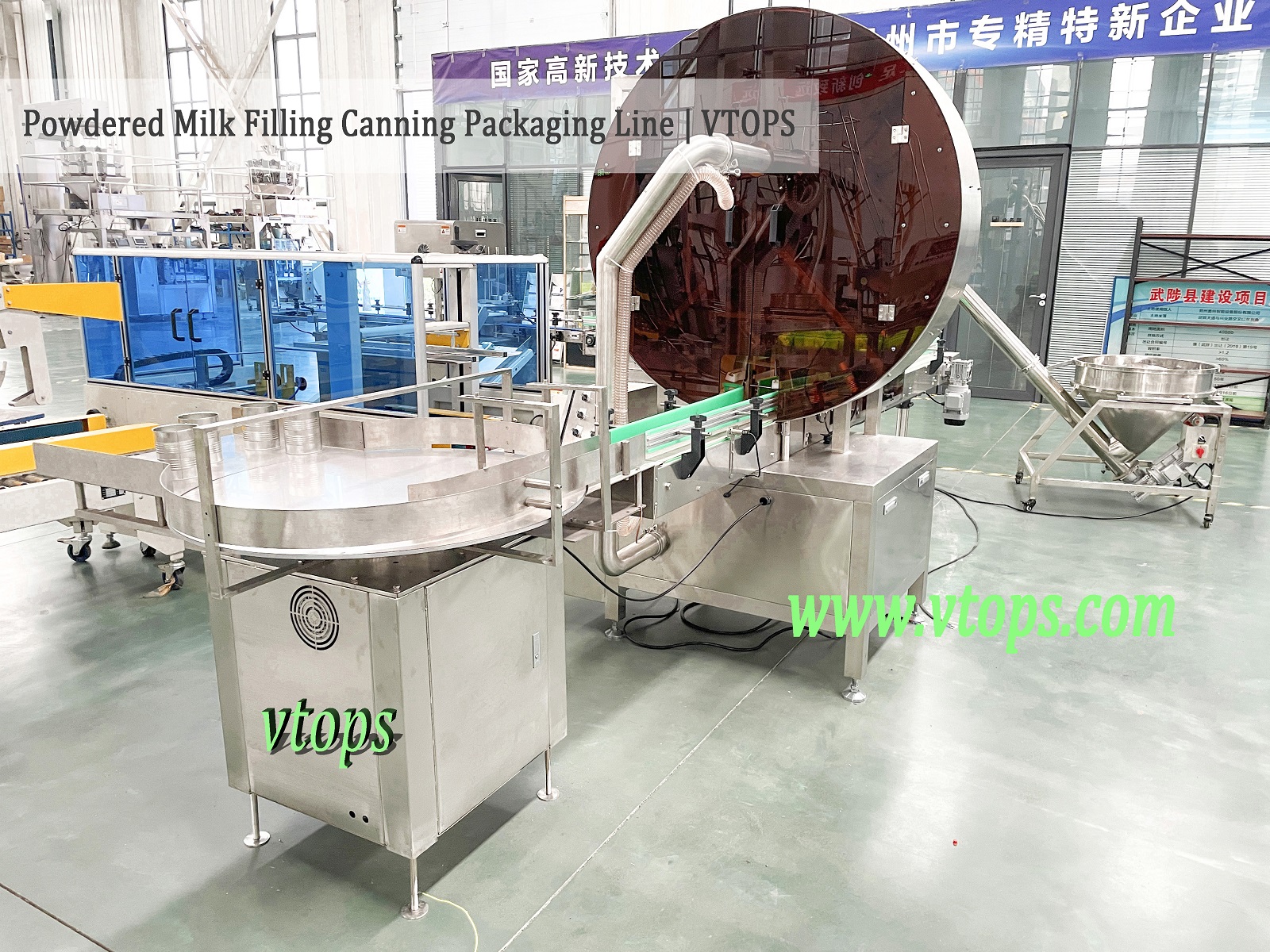

On October 15, 2021, Zhengzhou Vtops Machinery Co Ltd commissioned one regular set of powdered baby milk canning packing line. The powdered milk canning line reached the delivery standard and will be exported to Mexico. In the previous article, we introduced A Solution of Milk Powder Auger Filler Filling Machine for Metal Tin Can. A long time has passed and we have sold many powdered milk powder canning packing lines, but here we will introduce it again. The line will be exported to Mexico and the picture of this milk powder canning line is as follows: Powdered Baby Milk Canning Packing Line 211015

As shown in the figure above, this canning packing line includes 5 machines. They are following:

Powdered Baby Milk Canning Packing Line 211015

As shown in the figure above, this canning packing line includes 5 machines. They are following:

- 1, Tin Can Feeding Machine.

- 2, Empty Tin Can Sterilizing Machine (Non-magnetic).

- 3, Powdered Milk Auger Filling Machine.

- 4, Screw Conveyor Feeding Machine.

- 5, Tin Can Seaming Closing Machine.

1, Tin Can Feeding Machine:

A Tin Can Feeding Machine is a machine which is used to place containers, such as, metal tin cans, glass bottles, or plastic jars onto a conveyor belt at the start of the packaging line. After the container enters the feeding machine, it is driven by a variable-speed motor to make the container evenly enter the conveyor belt. It makes the packaging process more orderly and convenient. [product_carousel heading=”” heading_icon=”” item_width=”2″ crop=”” style=”plain_carousel” list_orderby=”date” list_order=”DESC” max_item=”100″ categories=”” ids=”4304″] According to the design requirements, the Cans Feeding Machine is an ideal choose to feeding circular containers. The maximum bottle feeding speed can reach 70 times per minute, but it limit by Due to the diameter of the container and rotary turntable. It is worth mentioning that the Tin Can Feeding Machine have a collection role if it place at the end of the production line. Empty Tin Can Feeding and Sterilizing Machine

Empty Tin Can Feeding and Sterilizing Machine

2, Empty Tin Can Sterilizing Machine (Non-magnetic):

The biggest advantage of Non-magnetic Empty Tin Can Sterilizing Machine is working in a non-magnetic environment. It will not cause the metal iron filings to be difficult to clean or cannot cleaned off due to the magnetic field. [product_carousel heading=”” heading_icon=”” item_width=”2″ crop=”” style=”plain_carousel” list_orderby=”date” list_order=”DESC” max_item=”100″ categories=”” ids=”6666″]Why necessary of Sterilizing Machine

As you know, babies have low immunity and weaker ability to fight external viruses. The manufacturing of tin cans involves multiple industrial processes. During these processes, these containers can become dusty or contaminated by other germs. Therefore, in the first step of baby food production, the tin cans should be disinfect first. Not only that, international packaging standards require all containers to rinsed or sterilized before they filled with products.3, Powdered Milk Auger Filling Machine:

For the dry milk powder auger filling machine, VTOPS is the best manufacturer without a doubt, at least we are proud to say so in China. We not only have more than 20 years of manufacturing experience in packaging machinery, but also have 40,000 square meters of modern industrial plants. Click here to learn more about the factory. You can find any auger filling solution you want from VTOPS. Powdered Milk Auger Filling Machine

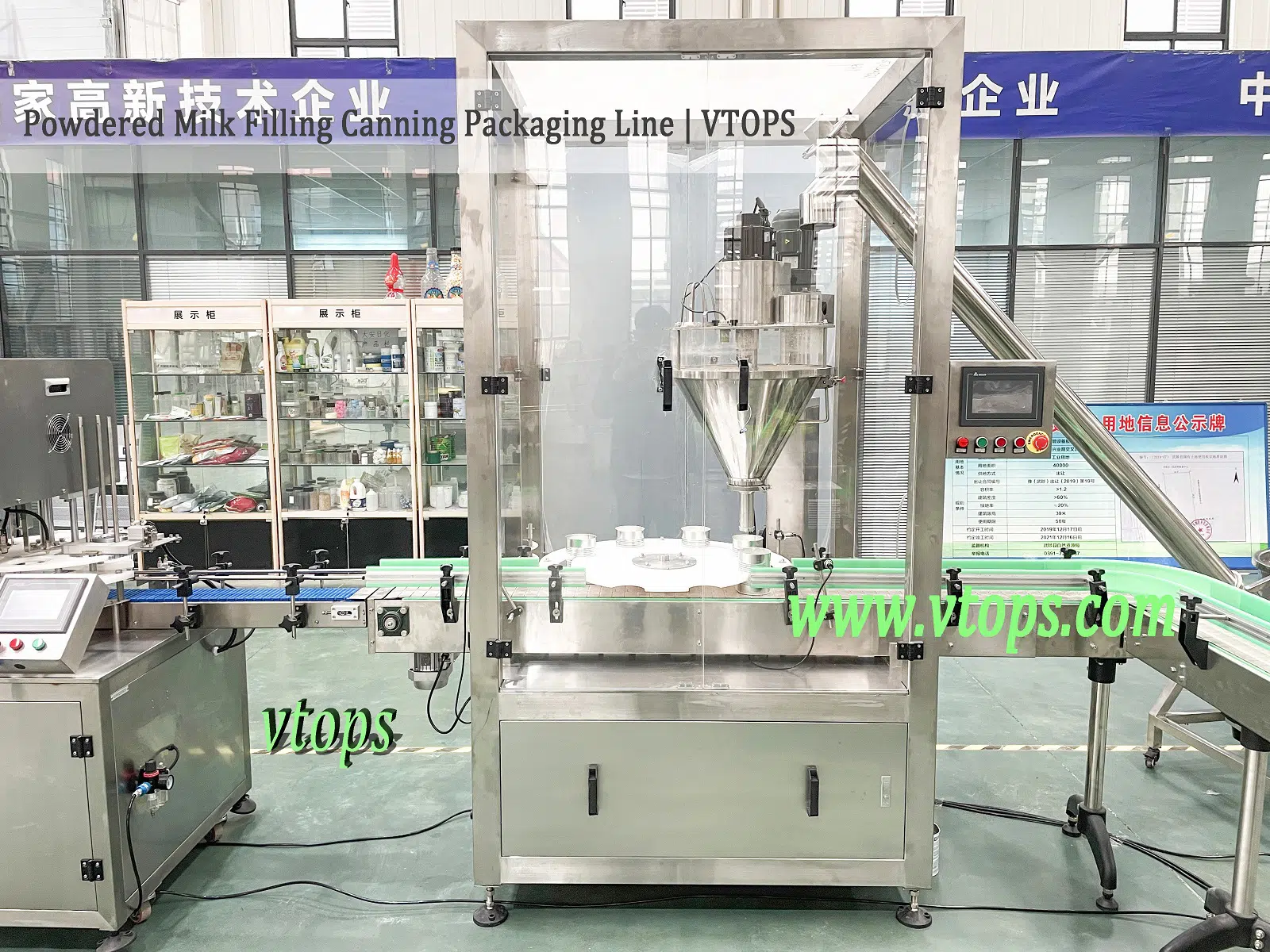

Powdered Milk Auger Filling Machine Powdered Milk Auger Filling Machine

Let’s go back to the topic, why the powdered baby milk need to be dosing and filling by an auger filling machine?

Because the powdered baby milk has a lot of dust in the dosing and filling. However, in order to avoid secondary pollution, the powdered baby milk must be metered and filled in sterile workshop. As you know, the biggest advantage of auger filling machine is that the filling systems are relatively closed. It makes the auger filler machine the ideal choice for filling very fine powders, such as powdered milk, talcs, flour, spice, and baking soda.

Regarding the powdered milk auger filling machine, there are many models in VTOPS to meet different needs. Please visit the Automatic Auger Filler Machine for more detailed information. It is worth mentioning that if your budget is sufficient, the super high filling accuracy of Fill-by-weight model is a worthwhile choice.

Powdered Milk Auger Filling Machine

Let’s go back to the topic, why the powdered baby milk need to be dosing and filling by an auger filling machine?

Because the powdered baby milk has a lot of dust in the dosing and filling. However, in order to avoid secondary pollution, the powdered baby milk must be metered and filled in sterile workshop. As you know, the biggest advantage of auger filling machine is that the filling systems are relatively closed. It makes the auger filler machine the ideal choice for filling very fine powders, such as powdered milk, talcs, flour, spice, and baking soda.

Regarding the powdered milk auger filling machine, there are many models in VTOPS to meet different needs. Please visit the Automatic Auger Filler Machine for more detailed information. It is worth mentioning that if your budget is sufficient, the super high filling accuracy of Fill-by-weight model is a worthwhile choice.

4, Screw Conveyor Feeding Machine:

The Screw Conveyor Feeding Machine is an auxiliary conveying device to the hopper of auger filling machine. [product_carousel heading=”” heading_icon=”” item_width=”2″ crop=”” style=”plain_carousel” list_orderby=”date” list_order=”DESC” max_item=”100″ categories=”” ids=”4312″] The conveyor feeder machine can be program through the program, and the milk powder change range does not exceed 5 cm in the hopper. Thereby reducing influence of filling accuracy due to the of gravity.5, Tin Can Seaming Closing Machine:

A Tin Can Seaming Closing Machine is used to hermetically seaming the metal lid to the body of cans. The can lid is usually made of tin-plated steel while the there are many different materials for the can body. Several known materials are following:- Metal Cans

- Paperboard Cans

- Plastic Cans

Tin Can Seaming Closing Machine

In addition, it is worth mentioning that the vacuum infill nitrogen seaming machine will be the mainstream trend in the future. The seaming machine evacuates the oxygen in the cans through a vacuum pump and injects it with inert gas nitrogen. It can greatly extend the shelf life of the food in the cans.

Tin Can Seaming Closing Machine

In addition, it is worth mentioning that the vacuum infill nitrogen seaming machine will be the mainstream trend in the future. The seaming machine evacuates the oxygen in the cans through a vacuum pump and injects it with inert gas nitrogen. It can greatly extend the shelf life of the food in the cans.

How Does the Powdered Milk Canning Packaging Line Work

The canning packing line designed to feature different processes and machines that work together resulting in a fully packaged product.Setp 1:

Firstly, the empty tin cans into the conveyor as predetermined. The Tin Can Feeding Machine designed to add in a specific number of empty cans to ensure the process runs smoothly.Setp 2:

Secondly, once the tin cans fed in, the next step is sterilizing. This is an important step to help avoid any contamination of your product.Setp 3:

Thirdly, after the cans are cleaned. They will go to the dosing and filling station if no need to add spoons to the cans. The auger filling nozzles will dispense the powdered baby milk into the cans. A branded sensors is enable the start of the filling process once the empty can gets to the filling station.Setp 4:

Fourth, after the products filled by the set weight.The cans will going to the seaming process to ensure the transportation safety and shelf life.Setp 5:

Fifth, The last step is to place the labels and the codes required for easy identification. Of course, the above process is just the simplest and most basic process. The actual process will be more complicate and more functional depends on your needs. For example, how to add a spoon to the jar, how to double confirm the filling weight, how to clean the seamed cans, and so on. If you want to know more detailed process, a reference video is following:Summarize of the Powdered Milk Filling Packing Line

The powdered baby milk filling canning packing line is not only using for packaging baby milk powder, but also protein powder, coffee powder and other natural powders. As a capable milk powder canned packagingline manufacturer for more than 20 years. Vtops create quality canning packing line, and provide custom solutions that will greatly serve the clients not only from Asia, but also from North America and Oceania. Click here and you will see the visit details of the clients from Australia.

In addition, Vtops Powdered Milk Canning Packing Systems feature some great advantages are the following:

Customization

An industrial workshop of 40,000 square meters is available to support any reasonable needs of you. Depending on your specific requirements as our client, we feature the ability to customize our canning systems. We do this to ensure that we cater to the specific requirements you have. Whether it is to increase production capacity or specific electrical configurations, we’ll get it done. We ask our clients to work closely with our designers to ensure they provide exact details of what they want with their canning lines.

High precision

The Powdered Milk Canning Packing Line are designed with the highest precision and efficiency to ensure that all the processes are accurate. Meanwhile, before handing over the canning packing systems to the clients, they conduct quality tests which involves automatic vacuum sealing performance tests and seam projector tests. By doing these different quality tests, they ensure their products are highly accurate in the applications.

Use of food-grade metal materials

All of the vtops packing machines made of the food-grade materials. Therefore, clients can use high quality machines which won’t contaminate their products.

One-stop Service

We are proud of being one-stop-shop because meet all service needs of clients accurately. We have their own designers who can help clients come up with a clear customization idea and achieve it. All the needs met at without being outsourced to other places.

We encourage you to bring your canning and packing needs to us and give us the opportunity to provide you with exactly what you need. We know that your products and business are valuable and when you choose one of our systems you are making a choice of guaranteed excellence. Warmly welcome customers from all over the world to cooperate with us for common success.