Things to Consider When Buying An Auger Filler Machine for Citric Acid Packaging

When selecting an auger filler machine for products like citric acid—which flows similarly to sugar—it is important to consider specific technical requirements and customization options to ensure efficiency, accuracy, and long-term reliability. Below, we’ve broken down the critical factors and solutions tailored to inquiries like the one submitted by David from Dover, MN, United States of America.

Key Considerations

1.Material Compatibility

- Citric Acid Properties: As a granular and free-flowing product, citric acid requires precise auger control to prevent spillage and ensure consistent filling.

Adding anti-free-flow devices is a useful little gadget can further enhance accuracy, especially for free-flowing materials like citric acid. These devices help control product flow and ensuring consistent weight measurements for every pouch. - Material Durability: Citric acid is slightly acidic and can corrode standard metals over time. Therefore, parts in contact with the product—the hopper, auger, spout, and transfer auger—must be made of 304L or 316L stainless steel. This material provides exceptional corrosion resistance and longevity, making it ideal for food-grade applications.

2. Ease of Cleaning

- Cleaning requirements for food-grade applications are stringent. Machines with quick-disassembly components ensure ease of cleaning and maintenance, saving time and effort.

3. Weight Range

- David’s inquiry specifies filling stand-up pouches with weights ranging from 1 lb (0.45 kg) to 15 lbs (6.8 kg). For this range, a machine capable of 0.5 kg to 10 kg filling volumes is suitable. Ensure the machine’s adjustable parameters can handle this spectrum without compromising accuracy or speed.

4. Spout Design

- The requested spout diameter is 1-1/2 inches. This dimension ensures smooth product flow into the pouches without clogging or creating a mess. Compatibility with the pouch opening is critical to prevent spillage and maintain clean operations.

5. Automation Level

- A semi-automatic auger filler allows manual placement of pouches while automating the filling process. This setup balances cost and efficiency for medium-scale operations.

6. Hopper Feeding System

- A transfer auger to refill the machine hopper ensures consistent operation by eliminating downtime for manual refilling. This feature is particularly important for handling larger pouch sizes and higher production volumes.

7. Delivery Location

- For David, the machine needs to be shipped to Dover, MN (ZIP Code 55929). VTOPS supports DDP (Delivered Duty Paid) delivery, ensuring the customer receives the machine directly at their warehouse without additional hassle.

Recommended Solution

Based on the requirements, here’s an ideal setup:

- Machine Model: A semi-automatic auger filler with a filling range of 0.5 kg to 10 kg.

- Material: All contact parts (hopper, auger, spout, transfer auger) made of 316L stainless steel for durability and food safety compliance.

- Spout Size: A 1-1/2” diameter spout to accommodate pouch openings.

- Additional Features: Integration with a transfer auger to maintain hopper levels during operation.

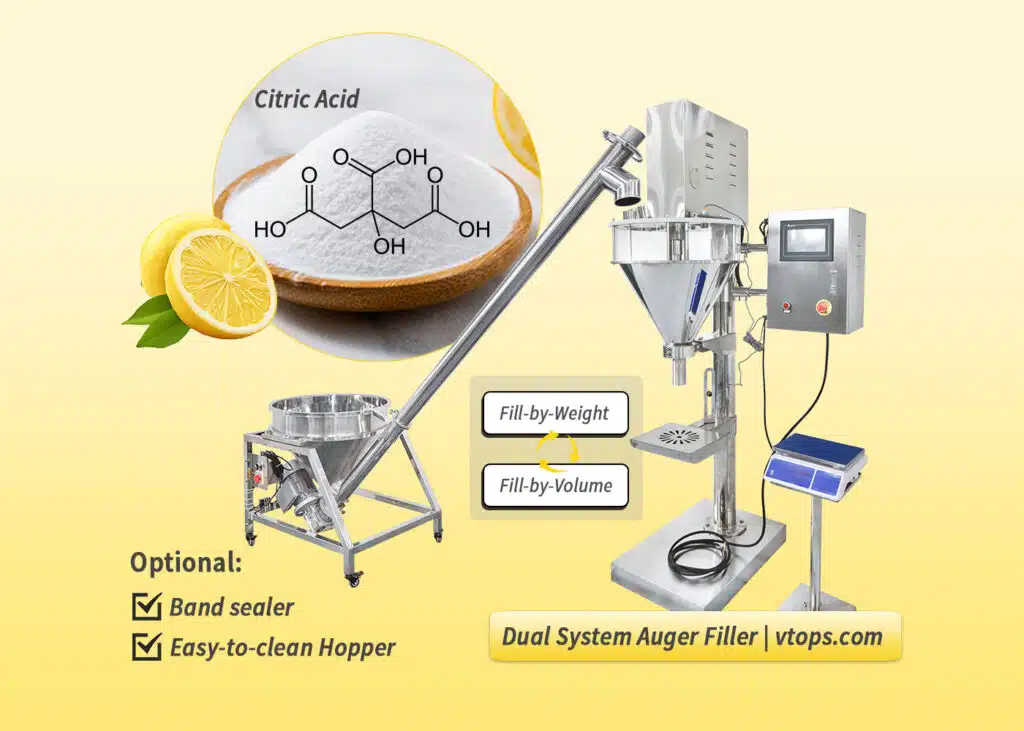

- Dual Filling System: The VTOPS auger filler machine offers dual-system filling, allowing users to switch between different modes as needed.

- Voltage and Compatibility: Ensure the machine’s power specifications align with U.S. standards (typically 110V or 220V, single-phase).

Why Choose VTOPS for Your Auger Filler Needs?

VTOPS specializes in designing and manufacturing high-quality auger filler machines, including:

- Customizable Solutions: Tailored spout sizes, material compatibility, and filling ranges.

- Durable Materials: 316L stainless steel construction for all product-contact parts.

- Efficient Systems: Integration with transfer augers for continuous production.

- Global Shipping Expertise: Ensuring safe and timely delivery to locations like Dover, MN.

- Delivery Convenience: DDP delivery options mean the machine arrives directly at your warehouse.

- After-Sales Support: A two-year warranty and comprehensive service ensure long-term performance and customer satisfaction.

Next Steps

If you’re in the market for a semi-automatic auger filler for citric acid or similar products, here are the next steps:

- Contact Us: Share your specific requirements, including product details, pouch sizes, and additional features needed.

- Request a Quote: We’ll provide a detailed proposal, including pricing, shipping, and estimated delivery timelines.

- Consult Our Experts: Our team can guide you in selecting the most suitable configuration for your production line.

By choosing the right machine tailored to your needs, you can enhance efficiency, reduce wastage, and ensure a long-lasting investment. Contact VTOPS today to get started!