A VFFS vertical form fill seal packing machine is a type of automated assembly-line product packaging system, commonly used in the packaging industry for food, and a wide variety of other products.

What is VFFS?

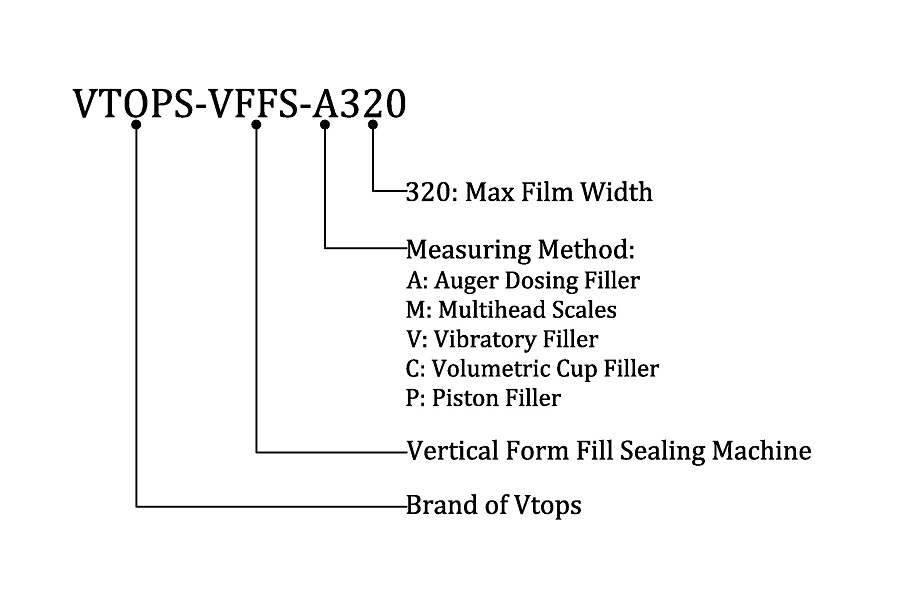

What Are the Models of Machine

The models of VFFS packaging machines are divided into 320, 420, 520, and 620, which are incremented according to the number of 100, and the largest model is 1020. These values represent the maximum film width (pouch unfolded), in other words, the bagging system available to handle the largest film width.. And prefixed brand and VFFS to these values to compose the VFFS models.

The Left Picture (click to enlarge) shows the detailed model parameters, including the VFFS manufacturer, the largest suitable film, and which metering and dosing system is equipped.

The biggest difference between these VFFS models is the width of the applicable film, please check the following parameters chapter or Inquiry Us to provide you with the most suitable solution.

Technical Parameters

| VFFS -320 | VFFS-420 | VFFS-520 | VFFS-720 | |

|---|---|---|---|---|

| Packing Speed | 5-70bags/min | 5-60bags/min | 5-50bags/min | 5-40bags/min |

| Bag Length | 50-200mm | 80-300mm | 100-400mm | 100-450mm |

| Bag Width | 50-150mm | 50-200mm | 100-250mm | 100-350mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| Filling Range | 50-800ml | 150-1200ml | 200-2000ml | 250-4000ml |

| Film Width | Max. 320mm | Max. 420mm | Max. 520mm | Max. 720mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Air Consumption | 0.3m3/min 0.65MPa | 0.3m3/min 0.65MPa | 0.4m3/min 0.65MPa | 0.4m3/min 0.65MPa |

| Voltage | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Power | 2.0kw | 2.2kw | 4kw | 4.5kw |

| Machine Dimensions | 117*82*129cm | 132*95*136cm | 149*108*149cm | 172*126*182cm |

| Machine Weight | 350kg | 550kg | 750kg | 850kg |

* The above are the model parameters of some VFFS packaging machines.

What are The Features

- 1. The new design, beautiful appearance, the structure is more reasonable, more advanced technology.

- 2. English and Chinese screen display. PLC control, servo motor, very easy to operate. Do not need to stop machine to adjust any parameters.

- 3. Fully automatic bag forming, dosing Filling, sealing, coding, conveying, counting can be finished in one operation, most labor-saving equipment.

- 4. High quality stainless steel, suitable for GMP, good for food packaging with high standard.

- 5. Horizontal, vertical temperature control, suitable for various of mix film, PE film packing material.

- 6. Pocket diversification, can provide customers with pillow bags, angled bags, hanging-hole bags, vertical bags, punched bags, etc.

- 7. A variety of automatic alarming protective function, maximum limit to reduce wear and tear.

- 8. Double sever motors, drawing film position accurately, and the speed is faster.

- 9. Temperature independent control system, precision get to ±1°C.

Applications

Vertical Form Fill Sealing Packaging Machine is used for packing many different products:

- 3.1 Food Industry: peanuts, popcorn, jelly, data, garlic, beans, grains, soybeans, pistachios, walnuts, rice, corn, sunflower seeds, melon seeds, coffee beans, ground coffee, potato chips, banana chips, plantain chips, chocolate ball, shrimp, sweet candy, sugar, tea, herbs, Chinese medicine, puffed food, dry food, frozen food, frozen vegetables, frozen pea, frozen fish ball, frozen pie, and other granule products.

- 3.2 Pet Food Industry: dog food, bird food, cat food, fish food, poultry food and etc.

- 3.3 Hardware Industry: plastic pipe elbows, nails, bolts and nuts, buckles, wire connectors, screws and other construction products.

What Pouch Styles can VFFS be Formed?

Wide variety of the pouch styles that VFFS machine can produce such as Pillow Bag, Pillow Gusset Bag, Continuous Bags and 3-sided Seal Bag those are used in dependence on the product shape and nature etc.

Please refer the photo of bag forms are the following:

Pillow Bag (Back Center Seal)

As per the name of the Pillow Bags (Back Center Seal), it forms the shape of a pillow. Once filled, it balloons from the middle and flattens out at the top and bottom seals.

tags: pillow bag pouch packing machine, back seal bag packing machine

3-sided Seal Bag

Three side seal bags allow more room for graphics with the elimination of the center back seal. Case packing and cartoning are simple and convenient with this bag style. Also known as a flat pouch, the 3 Side seal is Form Fill Seal Packaging to alternative of pre-made pouch.

tags: 3-sided Seal pouch packaging machine, three side seal bag packaging machine

Pillow Gusset Bag

Gusset Bags are flexible bags with an added piece of fabric called a “Gusset” to expand the bags’ original capacity. Moreover, the Gusset can create more volume and strengthen the bags’ structure. A Gusset Bag’s three basic measurements are its width, height, and bottom Gusset.

tags: gusset bag packaging machine

Block Bottom Seal

Stand-up Block Bottom Bags, central or offset back seal, whole range of reclosable features available. It combines the benefits of a traditional side gusseted bag and stand-up pouch and rolls it into a package that sits narrow on the shelf, doesn't tip over, and squares up like a box.

Continuous Bags

Continuous multiple pouch chained in a row. The number of serialized bags can be set as required.

Center Seal Stick

Center Seal Stick is also a form of back center seal packaging, which is usually a larger ratio of length to width.

tags: single lane stick pack machine, stick pack machine for sale, powder stick pack filling machine, stick packaging, omag stick pack machine, stick pack machine manufacturer, stick pack, stick packing machine, stick packaging machine, stick pack machine price,

Video Gallery

VTOPS-VFFS-V520 packaging machine for granular wheat seeds, which is measuring by Vibratory Weigh Filler.

VTOPS-VFFS-A320 packaging machine for dry milk powder, which is measuring by auger filler.

This is a small vertical pouch packaging machine, usually used for packaging film width less than 280 mm, or bag width less than 10 cm.

This is a small vertical packaging machine, usually used for packaging film width less than 280 mm, or bag width less than 10 cm.

(Maybe You Like) Whey Protein Powder High Accuracy Powdered Milk Auger Packing Machine with Fill-by-Weight System.

Verified by TÜV Rheinland, VTOPS is assessed, certified, authenticated and/or inspected by TÜV Rheinland.

How to choose right VFFS machine?

Pls tell us following points to choose a right model packing machine:

- 1. What product will you pack?

- 2. How many gram and volume in each bag?

- 3. What bag shape you want to get?

- 4. What is bag width and bag length?

- 5. What is bag material do you want to use?

Add-Ons Optional Function

- 1. Punching device for round hole or Euro slot.

- 2. Linking bag device

- 3. Stand bag device, for plug in at bag bottom.

- 4. Servo motor on horizontal sealing parts.

- 5. Special device if you use single layer PE film.

- 6. Nitrogen inflation device.

Product Showcase

The above five types of VFFS packaging machines are equipped with different metering and dosing devices. For example,

- Dry Powder VFFS packaging machine equipped with a Auger Dosing Filler

- Snack Food VFFS packaging machine equipped with Multi-head Weigher

- Granular Beans VFFS packaging machine equipped with Linear Vibration Scale

- Flowing Sugar VFFS packaging machine equipped with Volumetric Cup

- Liquid Sauce VFFS packaging machine VFFS equipped with Piston Pump Filler

tags: food packaging machine, packaging machine food,packaging food machine,

packaging machine for food, vffs packaging machine manufacturer,pouch packaging machine, candy packaging machine, coffee packaging machine, automatic packaging machine, automated packaging machine, packaging machine for powder, packaging sealing machine, cannabis packaging machine, packaging machine automation, packaging machine quotes, sauce packaging machine, powder packaging machine, liquid packaging machine, plastic packaging machine, doypack packaging machine, spices packaging machine, gummy packaging machine, vffs packaging machine, sachet packaging machine, spice packaging machine, condiment packaging machine, packaging machine for spices, vertical packaging machine, bag packaging machine, packaging machine supplier, snacks packaging machine, stick packaging machine, packaging machine company, beverage packaging machine, water packaging machine, beef jerky packaging machine, vertical form fill seal packaging machine

Add-Ons Auxiliary Equipments

Checkweigher Machine

Checkweigher machines are capable of weighing items produced on a production line. Common uses of checkweigher machines include: Determining underweight or overweight products.

Metal detector

A metal detector for the food industry can help ensure the safety and integrity of a wide range of unpackaged, packaged or bulk goods, by identifying metal contaminants during processing or packaging and helping to ensure that they do not enter food that we eat.

Finish product conveyor

Finished Product Conveyor is available to transport the finished goods to the platform.