Tooth powder is an oral care product, usually in powder form, to clean and care for the mouth. It is similar to toothpaste but unlike toothpaste. Tooth powder has a powder rather than a paste texture. Tooth powder removes dirt, food particles and plaque from the surface of the teeth, helping to keep the mouth clean and breath fresh.

Powder Characteristics of Tooth Powder

- Fluidity: Tooth powder usually has moderate fluidity. That enables it to disperse evenly in a moist environment and easily cover the tooth surface when brushing.

- Particle Size: The powder particles of tooth powder are usually very fine and small. It is helpful for people to effectively clean teeth and remove dirt and food residues.

- Consistency: Tooth powder powders typically have a low consistency, which means they are not too sticky and can be applied evenly.

- Tooth powder possesses a relatively low density, allowing it to dissolve readily in a humid environment. This dissolution also enables it to generate foam, enhancing the dispersion and cleaning of tooth surfaces.

What Machine Is Usually Used For Tooth Powder Packaging?

Tooth powder typically uses auger filling machines to pack, which efficiently and precisely fill tooth powder into various packaging containers. It can ensure that each package contains the exact dosage. In addition, other machines such as capping, packaging, and labeling machines can complete the production process of tooth powder products. These machines and equipment together constitute the packaging production line of tooth powder. They can meet the production requirements of different scales and needs.

VTOPS Provides Auger Filling Machine to Malaysia Tooth Powder Packer

Introduction of VTOPS

VTOPS is a company specializing in packaging machinery manufacturing. The company provides high-quality, high-efficiency filling, packaging, labeling, capping machines, and other equipment for various industries. VTOPS continues to develop and customize various filling solutions to meet the diverse needs of customers.

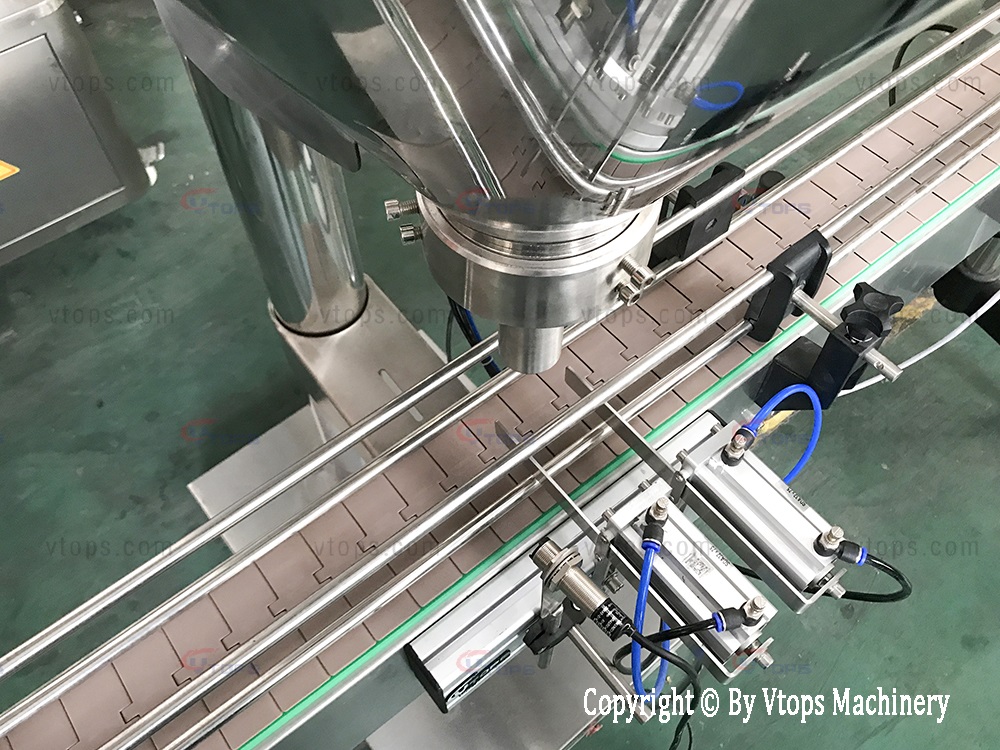

One of the main products VTOPS is proud of is the auger filling machine. Auger filler has matured after years of in-depth research and continuous technological innovation. The company has rich experience and excellent technical strength in auger filling machines. It is committed to providing customers with high-quality, high-performance solutions. Whether it is different types of products such as powder, granule, or liquid, VTOPS’ auger filling machines can meet customers’ filling needs and bring efficient and reliable performance to the production process.

Detail Photos:

VTOPS Provides Suitable Auger Filling Machine for Malaysian Customer

In October 2019, Mr Arvind Kumar from Malaysia contacted VTOPS. Mr. Arvind Kumar, a tooth powder packer, got in touch with a list of his needs for auger filling machines. After detailed communication with him, VTOPS finally put forward the most suitable suggestion to him, the VTOPS-PSH-01 auger filling machine.

The automatic auger filler of model VTOPS-PSH-01 is an economic linear type single-head auger filling machine. It has precise dosage control capability, efficient production speed and adaptability, easy operation and maintenance design, etc. The safety measures of the machine also comply with industry standards, which can effectively protect the safety of operators. Apart from this, the company also considered Mr. Arvind Kumar’s budget. Taking these conditions above into consideration, VTOPS-PSH-01 is his best choice.

What Requirements Should Be Met When Filling Tooth Powder with Auger Filling Machine

The requirements of tooth powder for auger filling machines are similar to those of other powder products. However, some special requirements exist because tooth powder requires higher hygienic standards and precise dosage control. The following are the main requirements of tooth powder for auger filling machine:

- Hygiene and Cleanliness: Tooth powder filling machines must meet extremely high hygiene standards. All parts and surfaces that come into contact with tooth powder must be easily to clean and sanitize. The aim is to prevent contamination and cross-contamination.

- Precise Dosage Control: The dosage of tooth powder needs to be very accurate to ensure that each package contains the correct dosage. Precise dosage control is critical to the function and effectiveness of tooth powders.

- Fluidity Control: The fluidity of the tooth powder needs to be controlled. That aims to ensure the powder can flow evenly during the filling process without clogging or jamming.

- Prevent Dust From Flying: During the filling process of tooth powder, dust should be prevented from flying. It can keep the working environment clean and the operator’s health.

- Adjustability: The filling machine should have adjustable parameters to adapt to tooth powder products of different specifications and packages. Different brands of tooth powder may have different dosage requirements.

- Packaging Adaptability: Packaging Adaptability: The filling machine should be able to adapt to different types of packaging. For example, bottles, tube containers, or bags to meet market demand.

- Precise Control System: The filling machine needs a high-precision control system to ensure that each filling is accurate and prevent over or under.

Commitment of VTOPS

VTOPS promises to provide customers excellent customer service, professional technical support, and perfect after-sales warranty service. The company is committed to providing customers with high-quality packaging machinery and equipment. It promises to support customers in selecting, installing and operating equipment with a professional attitude. In addition, VTOPS also pays attention to the long-term interests of customers. VTOPS promises to provide up to two years of after-sales warranty service to ensure customers enjoy long-lasting performance.

Conclusion

With the growth of people’s health awareness, more and more people realize the importance of oral hygiene to overall health. Therefore, using tooth powder has become a popular oral care trend. Many consumers love tooth powder because of its natural (plant extracts and herbs) and fine powder.

As a form of tooth powder packaging, the auger filling machine provides an efficient, accurate and hygienic packaging solution. VTOPS is committed to research and development, manufacturing and providing excellent solutions for auger filling machines. The company’s professional team adheres to the spirit of innovation and engineering excellence. It constantly strives to promote the development of auger-filling technology. If you have this demand, please contact us. VTOPS will provide you with the most professional advice and considerate service!

Delivery Photos:

-

- A total of 3 exporting wooden boxes.

- Marks: VTOPS DEST: MALAYSIA ITEM: POWDER FILLING MACHINE C/No. 1-3 / 2-3 / 3-3 MADE IN CHINA