How an Easy-to-Clean Hopper Improves Auger Filling Machine Performance: The Key to Efficient and Hygienic Powder Packaging

In the powder and granule packaging industry, Auger Filling Machines are widely used as an ideal choice for packaging dusty products due to their closed hopper design. They play a crucial role in industries such as food, pharmaceuticals, chemicals, and daily necessities. One critical factor in choosing an auger filling machine is the hopper design, which directly affects cleaning efficiency, material compatibility, and production safety.

To enhance productivity and meet hygiene standards, many manufacturers now prefer easy-to-clean hoppers. But why are they so essential? Let’s explore the key reasons.

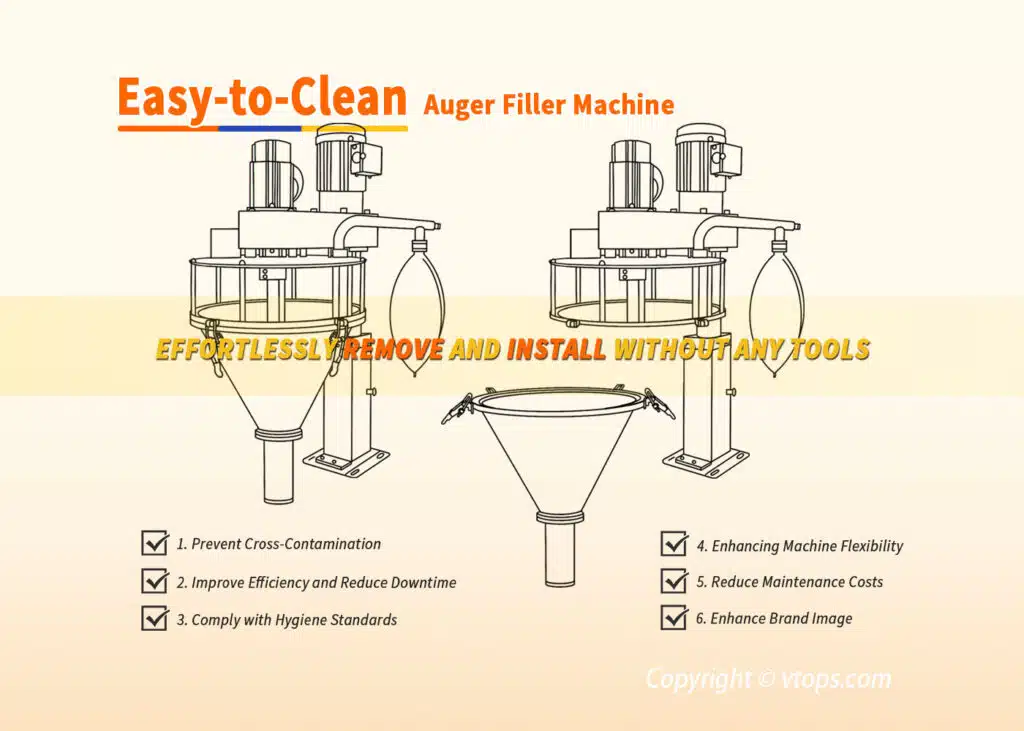

Quick Demo: How to Replace an Easy-to-Clean Hopper

To give you a more direct understanding of the convenience of an easy-to-clean hopper, we’ve prepared a demonstration video. This video showcases the quick disassembly and installation process, highlighting the design’s key advantages and ease of use.

Auger Filling Machine Easy-to-Clean Hopper Disassembly and Installation Steps 🛠️✨

In the video, you’ll see:

- Quick Disassembly: Effortlessly remove and install the hopper without any tools.

- Efficient Cleaning Steps: The polished stainless steel surface allows for easy removal of residual powders.

- User-Friendly Operation: Simple processes that any operator can follow, significantly reducing cleaning and changeover time.

If you’re looking for a packaging solution that simplifies maintenance and boosts production efficiency, this innovative design is a must-see!

1. Prevent Cross-Contamination

In industries where purity and hygiene are critical, residue from previous batches can contaminate the next production cycle, leading to:

- Changes in taste, color, or smell (food industry)

- Unstable formulations (pharmaceutical industry)

- Inconsistent product quality between batches (chemical industry)

An easy-to-clean hopper features a smooth stainless steel surface with no dead corners, allowing for fast and thorough removal of residual materials, reducing the risk of cross-contamination.

2. Improve Efficiency and Reduce Downtime

Cleaning and material changeovers take time, directly impacting production efficiency. Traditional welded or hard-to-disassemble hoppers require extensive cleaning, sometimes even partial disassembly of the machine.

In contrast, easy-to-clean hoppers come with:

- Quick-release structures (tool-free disassembly)

- Seamless, smooth interior to prevent material buildup

- Polished surfaces, making powder less likely to stick

These features significantly reduce cleaning time, minimizing downtime and increasing production efficiency.

3. Comply with Hygiene Standards

Industries like food and pharmaceuticals must adhere to strict safety and hygiene regulations, such as FDA, GMP, and HACCP. To meet these standards, an easy-to-clean hopper typically includes:

- Food-grade stainless steel (SUS304 or SUS316L)

- Electropolished or mirror-finished surfaces to prevent microbial growth

- Seamless and smooth design to eliminate powder accumulation points

Using a compliant, hygienic hopper helps businesses pass quality certifications and ensures product safety and regulatory compliance.

4. Enhancing Machine Flexibility

Many industries handle different types of powders, such as:

- Food industry: milk powder, flour, protein powder

- Pharmaceutical industry: medicinal powders, supplements

- Chemical industry: pigments, additives, metal powders

Traditional hoppers retain residual powder, leading to cross-contamination. However, easy-to-clean hoppers with quick-release and high-efficiency cleaning features allow manufacturers to switch between materials quickly, ensuring production flexibility and preventing contamination risks.

5. Reduce Maintenance Costs

Without proper cleaning, powder buildup can lead to:

- Hopper corrosion and rust, reducing its lifespan

- Moisture absorption and clumping, blocking the auger system

- Bacterial growth, compromising product quality

An easy-to-clean hopper provides multiple long-term benefits:

- Lower cleaning agent and labor costs

- Reduced wear and tear, extending machine life

- Prevention of mechanical failures due to powder accumulation

By reducing cleaning and maintenance efforts, manufacturers can save significant costs while maintaining efficient production.

6. Enhance Brand Image

For companies that export food, pharmaceuticals, or high-end consumer products, equipment hygiene directly affects consumer trust. Using an easy-to-clean hopper offers several advantages:

- Improved product safety, reducing complaints and recalls

- Compliance with international hygiene standards, facilitating global market entry

- A better corporate image, increasing customer confidence

In today’s highly competitive market, investing in hygienic and high-standard equipment helps businesses stand out and build a strong reputation.

Conclusion

Choosing an easy-to-clean hopper for your Auger Filling Machine is essential for ensuring product safety, improving production efficiency, reducing downtime, and complying with industry regulations. It also lowers maintenance costs and enhances market competitiveness.

For businesses that require high hygiene standards, frequent material changeovers, and efficient production, an easy-to-clean hopper is a must-have feature.

Looking for a high-performance auger filling machine with an easy-to-clean design? VTOPS offers industry-leading packaging solutions that meet international standards, ensuring efficiency, reliability, and hygiene in your production line.

Contact us today to find the best packaging solution for your business! 🚀