Quickly Touch

Product Categories

- Up to 2-year Warranty

- Dozens of Patents

- One-to-one Technical Support

- Install & Debug Video

- Custom Package Solution

- Global Local Service

Rotary Vibrating Sifter | Sieving Machine

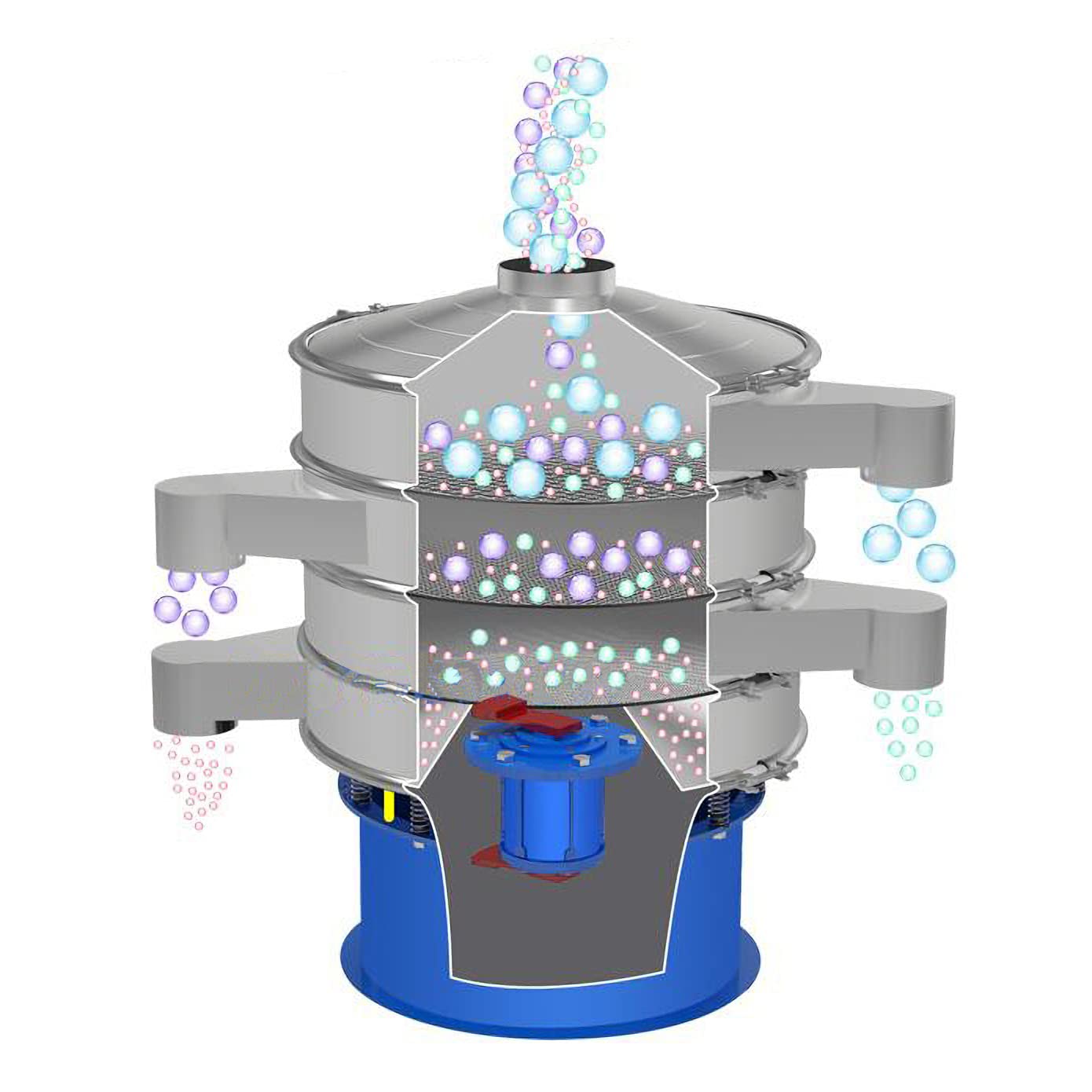

A vibrating sifter (also known as a sieving machine or a sieve) is a machine that separates materials into various sizes for different uses. Rotary vibrating sieve is composed of vertical motor,and eccentric weight installed at two ends.We can produce horizontal, vertical, inclined motions by adjusting the upper and lower eccentric weight.Diameter can be ranged from 400mm to 2000mm, with single or multiple screening decks(1-5 layers).

Working Principle:

Vibrating sifter is a vertical-motor system, with eccentric hammers being installed on top and bottom of the machine,where the vibration motor acts as the vibratory source.The direction of the eccentric hammers may change its rotational mode either in horizontal,vertical and inclined movement onto the sieving screener surface.

The machine’s operation can be described as follows:

- Feeding: The material is fed onto the sifter’s top screen.

- Sieving: The sifter uses a motor to generate vibrations, either directly or via another mechanism like a belt drive or eccentric weights. These vibrations cause the material to move across the screen’s surface.

- Separation: As the material moves across the screen, smaller particles pass through the mesh openings, effectively being ‘sieved’ from the larger particles. The size of the particles that can pass through is determined by the size of the mesh’s openings.

- Collection: The material that has passed through the mesh is collected in different grades or sizes, while the oversize particles that couldn’t pass through the mesh are discharged from an outlet.

Function:

- 1. Grading

This type of sifter machine can separate precisely and continuously,multi-layer type can separate different groups of particles at a time.It’s suitable for particle or other dry materials. - 2. Removing impurity

The rotary shaker machine can quickly separate a few oversize or undersized particles from your materials. - 3. Liquid-solid separation

The machines are used to remove solids from mixture of solid and liquid.

Technical Parameters:

| Model | Diameter | Effective Diameter |

Deck | Mesh Size | Power | Maximum Particle Diameter |

| S494-B | 430 mm | 0.13 mm | 1- 3 layers |

3-500 mesh |

0.25 kw | <20 mm |

| S496-B | 654 mm | 0.16 mm | 0.5 kw | <20 mm | ||

| S498-B | 800 mm | 0.44 mm | 0.75 kw | <30 mm | ||

| S4910-B | 950 mm | 0.63 mm | 0.8 kw | <30 mm | ||

| S4912-B | 1160 mm | 1.03 mm | 1.5 kw | <30 mm | ||

| S4915-B | 1500 mm | 1.65 mm | 2.2 kw | <50 mm | ||

| S4918-B | 1768 mm | 2.4 mm | 2.5 kw | <50 mm | ||

| S4920-B | 1950 mm | 2.98 mm | 2.5 kw | <60 mm |

Reviews

Rotary Vibrating Sifter | Sieving Machine

Follow Us

“There is no best, only better” are not just words to us but a way of life. We are able to better meet and exceed your diverse product needs by providing designs that are exactly suited to your requirements. Your satisfaction is our motivation.

Reviews

There are no reviews yet.