Quickly Touch

Product Categories

- Up to 2-year Warranty

- Dozens of Patents

- One-to-one Technical Support

- Install & Debug Video

- Custom Package Solution

- Global Local Service

Vacuum Conveyor Feeder for Bulk Dry Powders

Vacuum conveyor feeder is used with great advantage in conveying dry powder products through dedicated pipe systems.

Vtops’s vacuum conveying systems are built of high quality material. There are demands on the highest possible degree of safety as to hygiene and operation, when producing food, pharmaceuticals and chemical products.

How does Vacuum Conveying Work?

Vacuum Conveying is the process of moving bulk dry materials, such as powders, from place to place within a factory using suction. The material is transferred in a network of tubing from the pick up point or source to the customers process. Most Vacuum Conveying System transfer product based on a timed interval to the vacuum receiver. At the end of the timed sequence the discharge valve can open and the material conveyed can discharge in to the process.

There are two types of vacuum conveying. Dilute phase conveying and Dense phase conveying.

In Dilute phase conveying the material is entrained in the air stream and the is an almost equal part of air and product. This method is excellent for conveying almost any type of powder like sugar or flour.

In Dense pahse vacuum conveying the material is transferred in slugs within the convey tubing. The material moves slower then dliute phase conveying and is excellent choice for friable product or a blend of powders.

Schematic Diagram:

Image Description: Schematic Diagram of Vacuum Conveyor Feeder.

Image Description: Schematic Diagram of Vacuum Conveyor Feeder.

Features:

- 1. With high standard (GMP Standard, Sanitary Grade and Food Grade).

- 2. Made of nontoxic and corrosion resistant materials.

- 3. Materials are not adhering to the inner surface of conveyor.

- 4. Intelligent control and high automation.

- 5. Modular structure, Easy to Clean and dismantle.

- 6. Low noise and non-vibration.

- 7. More flexible to connect with filling packing machine, mixers, crusher, mills, etc.

- 8. Smaller footprint than screw conveyor feeder.

- 9. Good choice for powder, small pellet and fragile materials.

- 10. Low Energy Consumption.

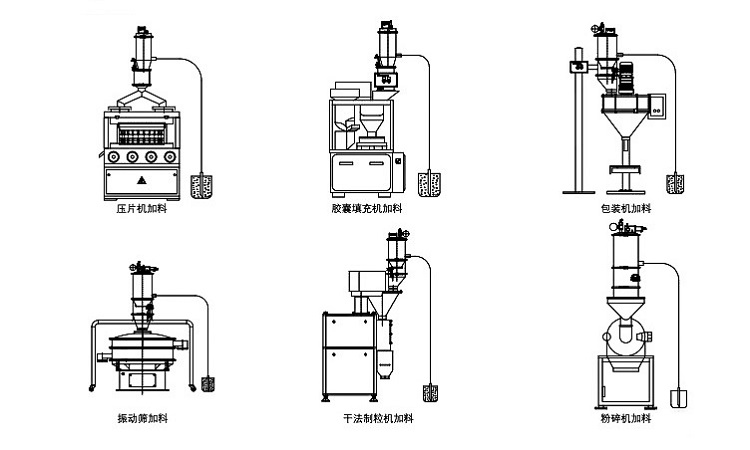

Applications of Vacuum Conveyor Feeder

Technical Parameters:

| Model | Capacity (kg/h) |

Vacuum pump type | Motor power (kw) |

Dimension of hopper (mm) |

Air pressure (Mpa) |

|---|---|---|---|---|---|

| VTOPS-F-VC1 | 400 | Vortex pump | 1.5 | Dia 220 * 820 | 0.6 |

| VTOPS-F-VC2 | 600 | Vortex pump | 2.2 | Dia 220 * 820 | 0.6 |

| VTOPS-F-VC3 | 1200 | Vortex pump | 3.0 | Dia 290 *950 | 0.6 |

| VTOPS-F-VC4 | 2000 | Vortex pump | 5.5 | Dia 420 * 1250 | 0.6 |

Reviews

Vacuum Conveyor Feeder for Bulk Dry Powders | VTOPS-F-VC

Follow Us

“There is no best, only better” are not just words to us but a way of life. We are able to better meet and exceed your diverse product needs by providing designs that are exactly suited to your requirements. Your satisfaction is our motivation.

Reviews

There are no reviews yet.