“Fill-By-Weight” is a specialized, ultra-precise filling technique. This method utilizes an Online-scale system that continuously monitors the filling weight and provides real-time feedback to the filling device, stopping the process as soon as the preset weight is reached. Simply put, it determines the quantity of a product based on Setting Weight rather than its volume or count.

The online-scale filling system is commonly employed in the packaging of products such as food, powders, liquids, or granular materials, where weight may vary due to factors like density. It is also used for products with higher value, where precise measurement is critical.

Key Points of Fill-By-Weight:

- Precision and Accuracy:

Fill-by-weight ensures that each package contains the exact Weight of product as specified by the manufacturer. This method is particularly important for products where the weight is directly related to the product’s value or effectiveness, such as pharmaceuticals or food. - Equipment:

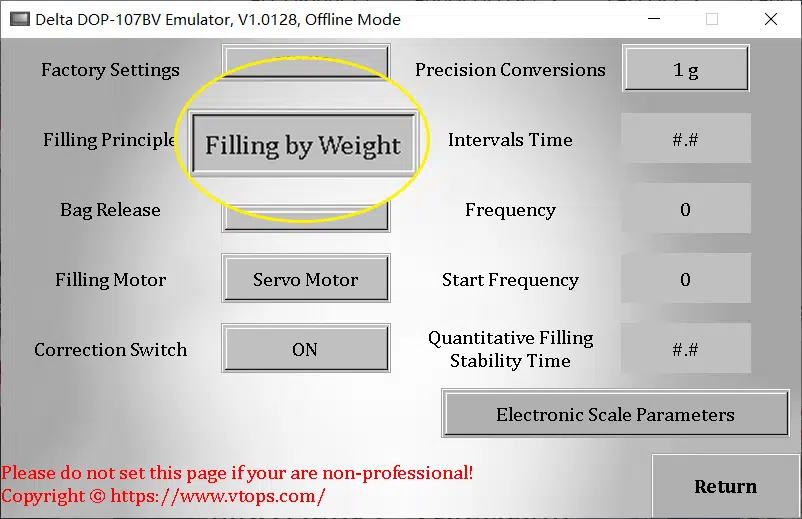

Specialized filling machinery is used in packaging industries to perform fill-by-weight operations. These filling machines typically incorporate filling systems, weighing feedback systems, online-scales, or load cells that measure the product’s weight as it is dispensed into packaging.

Setting Fill-by-Weight - Advantages:

Fill-by-weight is often more accurate for products that are difficult to measure by volume due to irregular shapes, density variations, or when handling bulk items.

It helps reduce the risk of underfilling or overfilling, thereby saving costs and improving customer satisfaction.

Additionally, for high-value products, it minimizes waste.

Conclusion:

Fill-by-weight is a precise filling method that ensures each unit of a product meets specific weight requirements. The packaging method contributing to high accuracy, quality, compliance, and customer satisfaction.